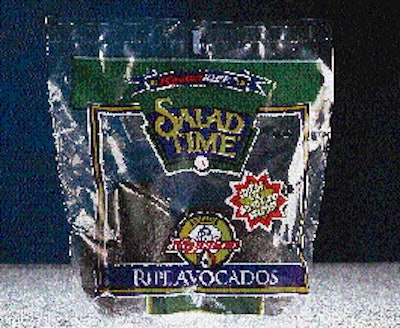

"We call it 'modified atmosphere packaging,' but you can call it profitable." That's how Mission Produce Inc. describes its MissionRIPE(TM) corrugated shipper in literature it sends to the foodservice and supermarket trade. Elsewhere, Oxnard, CA-based Mission uses words like "revolutionary," "patented," and "exclusive." All this to describe what appears to be a pretty ordinary-looking kraft box. The Tamfresh(TM) box, however, is anything but ordinary. Developed originally in Finland, it's now available through Pacific Asia Technologies (Vancouver, British Columbia, Canada). With a specially developed semi-permeable membrane, it provides another twist on MAP technology. Because the corrugated board incorporates this membrane in its inner liner, it controls the exchange of gases, specifically oxygen entering and carbon dioxide exiting. The result: a MAP system that extends the shelf life of whole produce by slowing down the ripening process. Believed to be the first to use Tamfresh technology in North America, Mission codes its boxes of avocados for three weeks from date of packing. Ripe avocados It's important to point out that Mission ships only ripe avocados in this box. In the past this was seldom, if ever, done because a ripe avocado must be consumed in just a few days. Consequently, the traditional approach for national distribution has been to pick avocados before they're ripe, and then pack, ship, and display them at retail while they're still green and hard. Consumers are accustomed to allowing a few days for in-home ripening. The MissionRIPE program upends tradition by giving avocado buyers-whether they be shoppers in the produce department or the guacamole maker in a large hotel-avocados that can be eaten immediately. "It's been proven that ripe avocados can outsell unripe avocados by a two-to-one margin," says company president Steve Barnard. Before Tamfresh arrived on the scene, Mission shipped some ripe avocados, but only locally. Now it can go nationwide. "We charge $1.50 more per box for the Tamfresh container compared to the conventional box we used for local distribution," says Barnard. "It comes out to something like three cents per avocado. But for that three cents, the benefits are substantial." Throughout 1995, Mission relied on prototype equipment to create the hermetic seal necessary in Tamfresh technology. Production was limited to about five boxes per minute. But in January, the firm installed two pieces of automated equipment, one for setting up the three-piece bliss-style box and the other for closing and sealing it. Now the company produces 30 boxes/min. Machine builders helped Stone Container (Chicago, IL) worked with Pacific Asia Technologies to develop the automated equipment and has an exclusive license for Tamfresh applications in North America. Stone also called on SWF (Sanger, CA) to modify a conventional SWF Bliss-Matic(TM) set-up machine for the Tamfresh program. The box is formed from two end panels and a body blank, but added to the machine is a special nozzle that applies a bead of "caulking" adhesive to the body blank precisely where the end panels meet the blank. The adhesive, designated HL7216 by supplier H.B. Fuller (St. Paul, MN), retains much of its pliability rather than drying to a hard consistency like conventional hot melt. This pliability is what ensures the hermetic seal. Body blanks and end panels are made by Stone. The outside liner and C-flute corrugating medium are standard mill grades of containerboard. But the inside liner is an extrusion lamination of two layers of kraft paper, and an unidentified extrudate that provides the controlled permeability. Pacific Asia Technologies' Bill Powrie says only that it's a copolymer, without naming the converter that provides the lamination. One detail Powrie does provide is that the layer of paper that ultimately comes into contact with the avocados is sorbable so that droplets of water resulting from condensation won't slide to the bottom and form a pool. If such a pool were allowed to form, microbial growth could become a problem, says Powrie. He also adds that a patent is pending on the Tamfresh technology and he expects it to be issued in the next few months. Grading is first At Mission's plant, the avocados are first sent through an "optic grader" that lets Mission guarantee shape, size and maturity of each piece of fruit that goes into its MissionRipe box. The fruit is loaded manually after a molded pulp tray with a cavity for each avocado is placed in the bottom of the box. Workers also cover the first layer with a foam pad before placing a second layer of avocados on top. Then the workers mark the use-by date and the case count, which is anywhere from 32 to 84 depending on size, but usually around 48. Finally, the boxes are sent through the specially built three-side sealer from Stone. Left and right flaps are positioned vertically when the box enters the machine. The right flap is immediately plowed down to a horizontal position. Its extreme outer edge is run through a taping head that applies a 2"-wide strip of clear plastic tape to the top of the flap and then folds the tape over the edge and compresses it to the bottom side of the flap. This seals off the open flutes of the flap edge so that the MAP gases won't leak out of the box through the flutes. The taped right flap is plowed closed and a heavy bead of ordinary hot melt is applied along its length by a Nordson (Duluth, GA) unit. Then the left flap is plowed closed on top of the right flap and held there by a top compression bar. The case now enters a right-angle transfer. On opposite sides are glue heads, two per side. The first applies the Fuller caulking adhesive in the corner where the side flap meets the end panel. The applicator puts a bead of conventional hot melt for sealing the flap to the end panel after the flap has been plowed closed. All that remains is a quick pass through side compression rollers and the hermetically sealed case is complete. The arrival of this automated packaging system means a lot to Mission's marketing strategy. "As long as we were limited to five cases/per minute, we kind of laid back a bit and were careful not to oversell the MissionRIPE program," says Barnard. "But now that's changed. We're ready to go." Partners in produce So is the ever-innovative produce marketer Tanimura & Antle of Salinas, CA (see PW, October '95, p. 40 and January '96, p. 2). A leader in the burgeoning fresh-cut-and-packaged produce category with its SaladTime family of salads and other veggies, T&A is teaming up with Mission to sell avocados in 2-count clear bags at retail. The bags are decorated with high-impact graphics that include the recognizeable "Salad Time" logo as well as a prominent "MissionRIPE" banner overhead. The bags have air holes in them, as barrier properties are not an issue at this point. What is an issue, says Barnard, is the feel of the bag in the consumer's hands. That's why a 2-mil polypropylene was selected for the bag material rather than something like a low-density polyethylene. "I wanted a crinkly material that felt like a T&A salad bag," says Barnard, who relies on several sources for the bag. "Polyethylene feels too much like a baggie." The bags carry handling, preparation, and serving instructions printed on the back. Mission bags the avocados before loading the two-pack bags in the same Tamfresh box used for unbagged avocados. At the supermarket, the avocados are merchandised right alongside T&A's other prominently branded offerings. Pricing varies with the price of avocados, says Barnard, but currently the two-packs retail for about $1.99. Now entering its second year of the MissionRIPE program-and the first year in which true commercial-scale packaging equipment was available-Mission's Barnard is excited by the prospects. "We've had some challenges, and we're still making adjustments," he says. "But we know it works. Remember, if it had been easy, someone would have done it a long time ago." Mission's willingness to push forward to commercialize the unusual technology may pay big dividends, especially since the firm has exclusive rights to the Tamfresh box, at least for avocado packaging, for several years.