When Hurricane Katrina hit Mississippi in late August 2005, the Biloxi shrimp processing and packaging plant of C.F. Gollott & Sons Seafood was destroyed. The family-owned firm could no longer process and package its range of shrimp products (whole, deheaded, peeled, and deveined varieties) in 5-lb bags for foodservice and retail markets nationwide. As the five Gollott brothers (Brian, Arnie Jr., Dale, Nicky, and Ben—sons of Arnie Gollott Sr. and grandsons of original founder, C.F. Gollott) made plans to rebuild the facility, they decided that they would install automated bagging equipment to replace the previous manual shrimp-bagging operations.

Co-owner Brian Gollott notes, “We had not been dissatisfied with the manual bagging operations in the old plant. Our packaging staff did an excellent job. But in the course of rebuilding, we saw an opportunity to upgrade our packaging efficiencies even further to increase production rates for our growing customer base and decrease product giveaway.”

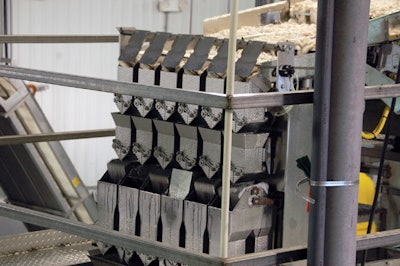

The company looked around at available scale and bagging systems, and co-owner Arnie Gollott came across the Advantage vertical form/fill/seal bagger (Model B3PF) and the Selectacom scale (model A612SHH2) from Triangle Package Machinery.

“The people from Triangle explained in detail how the equipment could work for us and handle wet, sticky products like fresh shrimp. They really did due diligence in helping us install the system, train our workers, and start up the line,” says Brian Gollott.

As auxiliary equipment for the new scale and bagger, Gollot installed new lift belts and inspection belts custom-engineered by Biloxi-based Dellinger Sheet Metal (228/432-7164).

New operation

In May 2007, C.F. Gollott & Sons began operations at the new plant. The 5-lb portions of shrimp are automatically weighed by the Triangle Selectacom scale and are loaded into bags formed by the Triangle Advantage vertical f/f/s bagging machine. A clear 2.5-mil unprinted rollstock film (provided by multiple suppliers) is used to form the bags. The bags are date-coded using thermal heat-transfer coding equipment from Markem, which Triangle has integrated into the Advantage bagging machinery. Under the old manual bagging system, the company used preformed bags, which were more expensive than the rollstock film.

Brian Gollott notes, “The exact scale system is impeccable and minimizes product giveaway. With the manual weighing and bagging system, we had been averaging product giveaway of up to four ounces per bag in the form of overfills. Now overfills are almost nil. At the same time, our bagging speeds have doubled from approximately 2,000 pounds of shrimp per hour with the manual system to 4,000 pounds per hour with the automated system.”

Currently, C.F. Gollott is only producing 5-lb bags of shrimp. But Brian Gollott points out that the new automated system offers the company the versatility to run from 8-oz to 10-lb bags if they choose to add other packaging sizes to the product mix in the future.

After the bags are formed, filled, and heat-sealed, they are manually loaded into three-color preprinted, wax-coated, paperboard boxes supplied by Livingston Box Co. The boxes are then channeled through a blast freezer before being loaded in 10-counts into master shippers (provided by multiple corrugated case suppliers).

In addition to doubling shrimp-bagging speeds and cutting product giveaway, the automated bagging system also has enabled about a 15% to 20% savings in labor costs. Brian Gollott reports, “The all-stainless-steel equipment is very manageable in terms of maintenance and clean-up. And we get great technical support from Triangle. We don’t know the exact payback time on the system yet, but my brothers and I are very happy with what we’ve seen so far.”

For related articles visit packworld.com/seafood