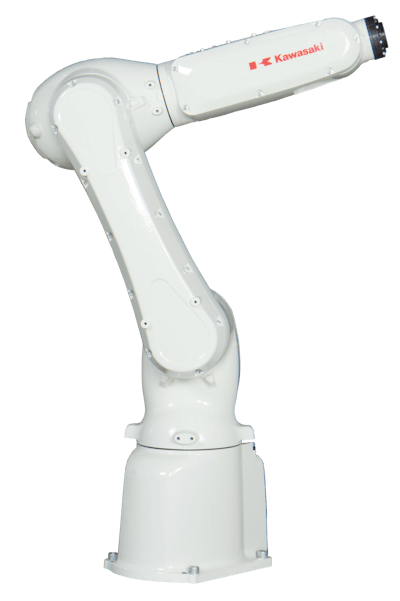

Superior Speed

Both the Kawasaki RS007N and RS007L robots continue to offer the operational advantages of the R series robots while incorporating a newly redesigned arm structure and main-unit weight reductions. These enhancements result in the fastest operating speeds in these robots' class (12,100 mm/s) along with increased working ranges. By redesigning the arm structure and adjusting the acceleration rates in accordance with load weights and robot positioning, these models also offer consistently optimized performance by significantly reducing cycle times.

Expanded Working Range

The expanded reach offers greater flexibility in production facility layouts. By utilizing a cantilever design for the upper arm section, Kawasaki has achieved a longer maximum reach and an expanded range of motion: below, behind and in the immediate vicinity of the robot. Additionally, these floor or ceiling mount models are designed to house vision cables, sensor harnesses, air lines and other components inside the arm structure. This prevents interference with and from peripheral equipment, thus allowing for operation in tight installation spaces.

First Rate Environmental Protection

The RS007N and RS007L robots feature a double-seal construction on all axes and waterproof electrical connections, offering an IP67 classification for the wrist and IP65 for the remaining axes. This first rate environmental protection means the robots are protected against large quantities of dust, water, lubricants, coolants, and can even withstand high surface temperatures and temporary submersion.

Controller

The RS007N and RS007L robots come standard with Kawasaki’s newest F60 robot controller. This state-of-the-art controller helps manufacturers digitally connect their machines and extract value from the Internet of Things (IoT), and features enhanced data collection and transfer capabilities to support overall equipment efficiency (OEE) calculations and smart manufacturing. The Bluetooth enabled controller allows for the collection and analysis of both robot and production data and provides the ability to link to the cloud, other robots or machines, tablets, vision cameras and various fieldbuses.