This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

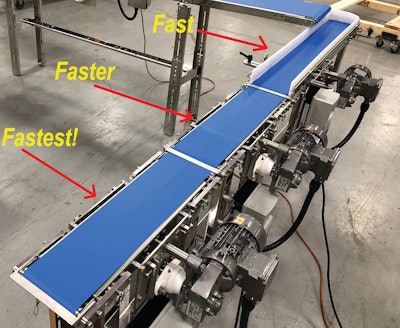

Product gently transfers onto three in-line Slim-Fit conveyors that progressively accelerate in speed to a “pull” a minimum gap before end transferring onto a check-weigher prior to a hand-pack station.

Individual single row product will gently cascade and 90 degree transfer onto the first section that incorporates custom guiding to form a back stop and side rail to minimize product bounce.

Product then runs through two more conveyor sections at progressively faster belt speeds. This results in a larger product gap due to speed ratio..

Deadplate transfers ensured the individual products' smooth transition without stall—even at increasingly higher line speeds. The transfer plates are simply removed for maintenance or cleaning.

Belt tracking is easily adjustable to compensate for uneven belt wear or belt stretch over time. Washdown rated local VFD’s were also supplied for individual motor control and rapid change over between products.

Our standard Slim-Fit series is pre-engineered, quality-built, affordable, stainless steel, sanitary, and features tool-less pin-pull belt removal. Learn more about the Slim-Fit here.

View this machine on YouTube at: https://youtu.be/HPOWuLXqVC0).

NOTE: Products used in this video are for demonstration purposes only.