This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

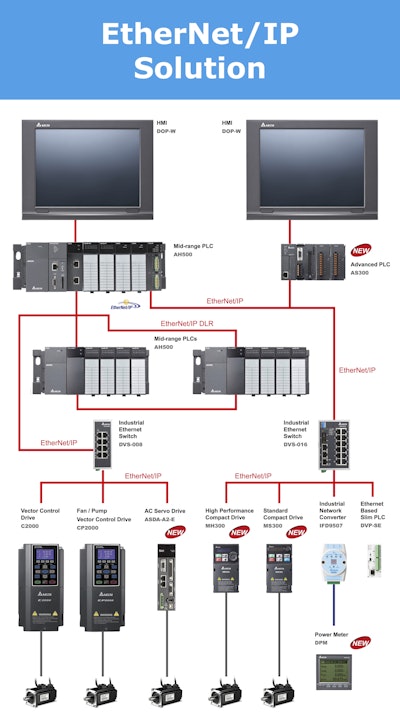

According to Remy Echavarria, PLC/HMI product manager at Delta Products Corporation, “Delta has been embedding the complete functional stack of EtherNet/IP networking protocol for both client and server devices – allowing us to interconnect a wider range of Delta technology with 3rd party systems to allow users to take advantage of more effective solution architectures.”

Recent additions of E/IP have been made to the AS300 series compact modular mid-range PLC, the DVP-ES2-E series PLC, the AH500 advanced CPU, and the new AH10EMC integrated EtherCAT motion & PLC CPU for the AH500 series mid-range rack PLC. This supports an even stronger system configuration when combined with other Delta Industrial Automation Technology including:

• C2000 general purpose VFD

• MS300/MH300 compact micro VFD

• DOP-100 HMI

• DVS managed & unmanaged Ethernet switches

• IFD9507 industrial network converter module

• DVP-SE Ethernet based Slim PLC

• DVP-ES2-E Ethernet based Compact Micro-brick PLC

According to HMS Industrial Networks, EtherNet/IP is the fastest growing within industrial Ethernet globally and has over taken DeviceNet fieldbus in terms of market share in the U.S. Delta’s PLC systems and industrial networking converter modules support multiple Ethernet and fieldbus networks to bridge the plant modernization gap and allow legacy systems to connect with new upgraded machinery.

As Delta continues to expand its range of Industrial Automation Technology, EtherNet/IP will become a standard across the board. Delta technology has always included Modbus serial and Modbus TCP as standard protocols on every IA device, EtherNet/IP has been chosen as a standard to increase full range information connectivity with other popular automation devices and suppliers in the Americas.