This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

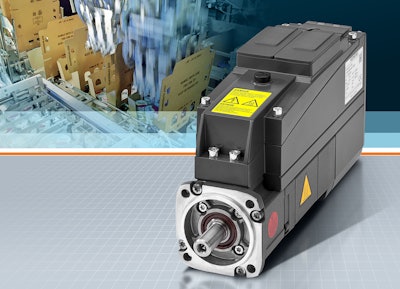

The Sinamics S120M is a compact, ready-to-connect motor with integrated drive that offers users the option of moving the motor inverter outside the control cabinet and directly onto the motor, thereby reducing both cabinet space and required cooling.

The addition of the Sinamics S120M distributed format into the S120 offering adds a high degree of flexibility for new and existing machines, as well as introducing innovative production line setups that can now be achieved.

Typical applications for the Sinamics S120M include packaging, printing, glass, textile and other processes, where machinery and production lines require multiple servo axes in a space-restricted environment.

The decentralized S120M axes are connected back to the central S120 components in the cabinet via a hybrid cable and the AM600 adapter module. The pre-assembled hybrid cable contains all encoder and power cables and serves multiple S120M axes through a daisy chain connection. This single-cable solution drastically reduces the number and length of cables and is easily expanded for additional axes.

As a fully integrated format of the Sinamics S120 drive system, all existing Safety Integrated functions and communication options are available, and the benefits of power sharing between axes across the DC bus are completely realized. Additional design features of the S120M include a synchronous servomotor with multi-turn absolute encoder, optional holding brake and an integrated power unit (motor module) available in three shaft heights covering the power range of 0.25–1.5 kW.