During the Packaging Conference 2017, the use of PEN (polyethylene naphthalate) as part of a PEN/PET copolymer generated some interest, but in large part, we haven’t heard a great deal about its use in packaging applications for a while.

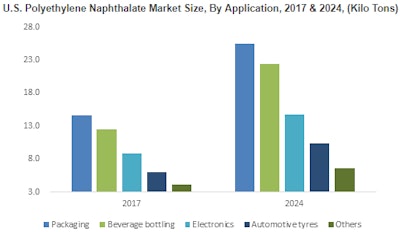

A new research report by Global Market Insights, Inc., however, says otherwise. It estimates the U.S. PEN market from packaging applications may exceed $640 million by 2024. The forecast says PEN is “used for food packaging applications as it provides high-barrier properties and [is] less permeable to water vapor and oxygen. Additionally, [PEN] reduces oxidation effects in containers, making it ideal for food preservation purposes. These resins are used to manufacture pellets and films which are thin, flexible, and durable, thereby preventing chemical gases and moisture from entering the packaged food products.[PEN] reduces the number of required layers, thereby enabling simplification of packaging structure along with reducing overall packaging costs.”

GMI says the PEN market size from beverage bottling applications was valued at over $280 million in 2017, pointing to the production of “beer and juice bottles as the material provides high oxygen and moisture barriers of about five times more than PET and is considered [a] most effective mono material. Also, these products provide durability when exposed to high temperatures.”

Further PEN benefits, says the report, include “superior properties such as heat resistance, low oligomer extraction, strength and dimensional stability. Increasing consumer preferences towards shatter-proof and light-weight beer and juice bottles may further support market growth.”

Another PEN growth area is in films, with industries such as automotive, electronics, food and beverage packaging helping to accelerate market growth. Overall, GMA forecasts the PEN market to surpass $1.8 billion by 2024.