Effects of FSMA on food and packaging safety

New industry regulations can be the source of fear and trepidation, particularly in the case of the U.S. Food and Drug Administration’s Food Safety Modernization Act (FSMA), for which many details and guidances have yet to emerge.

Still, in the first quarter of 2014, when we surveyed production and packaging professionals at U.S. food and beverage facilities, the results painted a more optimistic picture of industry compliance. A large majority reported that they have already completed the law’s key requirements. And an overwhelming majority incorporate packaging into their food safety plans, or will in the coming year despite a historic paucity of specific standards or compliance tools to aid in this effort.

The findings, while representing only a snapshot of a cross-section of companies, echo this view by industry experts: The FSMA, while a catalyst for reviewing food safety management practices, is consistent with existing market requirements, and should not cause management or operational upheavals for firms that already follow accepted food safety standards and procedures. Here are two of the findings:

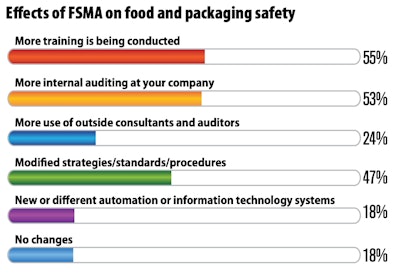

Effects of FSMA on food and packaging safety

As shown in Fig.1, food safety training and internal auditing activities have risen for a majority of food companies, albeit a small majority. Likewise, a large majority have modified their overall food safety strategies, but this does not translate into a significant rise in the use of outside consultants or upgrades to automation or IT systems that may improve track/trace and enhanced recordkeeping as the industry awaits the emergence of final provisions and guidance documents.

Level of completion for major FSMA requirements

A huge majority of companies report full completion and implementation with the seven major requirement areas of FSMA as summarized by the Grocery Manufacturers Association—first and foremost in the areas most deeply embedded in the industry’s long-standing practice of Hazard Analysis & Critical Control Points (HACCP) programs. (See Fig.2) While a strong majority reports compliance across the board, areas for additional activities tend toward “meta” considerations involving verification, validation, and recordkeeping.

Other findings in the survey relate to:

- The role packaging plays in plants' food safety management (and specifically HACCP) plans,

- The frequency with which companies conduct of packaging material supplier audits,

- How companies expect FSMA to change the frequency of those audits, and

- The percentage of facilities certified, or in the process of certifying to a standard accepted by GFSI, the Global Food Safety Initiative.

For full results and a full discussion of FSMA compliance-related packaging issues, download the entire Food Safety Playbook.