Packaging machinery forum in Germany outlines next generation design requirements

On March 11 and 12 a Who’s Who of European packaging machine builders participated in The Future of Packaging Engineering Forum in the city of Marktheidenfeld some 50 miles east of Frankfurt.

The thirty attending design engineering directors represented Gen3 machine builders from such respected companies as ALPMA ALS Buehler Bindler ECH Focke Harro Hoefliger HEITEC IWK Kallfass Optima Pester Pac Bosch SIG Pack Systems Somic Vetter Uhlmann Weber and Wilhelm Bahmueller.

They gathered to catch a glimpse of what will follow Generation 3 packaging machinery the so-called Gen4 machinery that might logically be expected to fill the halls of the Interpack show in 2005. What will characterize Gen4?

In a word software

Presenters explained the impact of increasing software content in packaging machinery and what engineering departments will need to do to manage software quality in design projects.

Dr. Klaus Bender Professor of the Technical University of Munich predicted that by 2010 60% of machine cost will be software with mechanical and electronic content accounting for roughly 20% each.

This is in marked contrast to today’s Gen3 machines in which roughly 40% of cost is software 20% is electronic and fully 40% is still mechanical.

It’s interesting to note that electronic cost is not projected to increase. This can be attributed to continuing hardware cost reduction and the replacement of discrete hardware by software modules.

Dr. Bender advised the audience to beware of increasing software complexity. Then he outlined a development model to manage interdisciplinary engineering processes.

Gen3: a scalable foundation for the next generation

Dr. Thomas Cord Research and Development Manager for ELAU identified trends and corresponding technologies. Key among these are simplified operation and diagnostics processing and packaging line integration vertical integration with MES systems and expanded regulatory compliance requirements.

It was clear from Dr. Cord’s presentation that the technologies enabling Gen3 – such as integrating motion and logic on a Pentium M class processor – provide a scalable foundation for next generation software developments.

The event which was hosted by ELAU concluded with a tour of the company’s manufacturing and applications research facilities.

Software “quality gates”

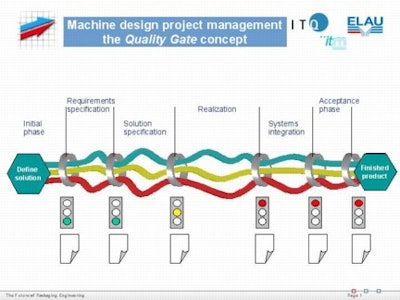

Software quality consultancy ITQ contributed a comprehensive roadmap for project management. ITQ President Dr. Rainer Stetter completely overturned the traditional approach in which control systems follow mechanical design. His model described a methodical sequence of design reviews testing and documentation at distinct intervals through the project cycle. ITQ Project Leader Harold Weigold gave real world examples of thismodel which the firm calls the “quality gate concept.”

Additional in-depth sessions were led by Joerg Riekenbrauck Uhlmann Pac System’s Chief of Electronic Development and ELAU’s Marc Slotman Training Manager and Dietmar Hamburger Applications Manager.

The workshops demonstrated how commercially available development environments such as ELAU’s EPAS-4 software toolkit can accommodate the new techniques today.

“We must completely redesign our machinery!”

OEM participants concurred that for the next generation “we must completely redesign our machinery!”

This may seem inconceivable to the US packaging industry where Gen3 is only now taking hold. How could it be that ‘Gen4’ is only a few years away from commercialization in Europe?

But perhaps it’s not such a big leap. Unlike the radical shift from mechanical/servo Gen2 hybrids to servo-centric Gen3 designs the next generation will build on today’s scalable standards-based hardware and software foundation.

As this forum suggests the keys will be interdisciplinary project management platforms that can accommodate new software and communications capabilities and an increased focus on modularizing complex capabilities.

To schedule a presentation in North America on next generation packaging machinery design processes contact John Kowal Global Marketing Manager ELAU Inc. at 773 342 8400 or email [email protected].