Author - Elisabeth Cuneo, Contributing Editor, PMMI ProSource

Any equipment purchase is a big deal. Knowing the in’s and out’s of your project -- and how you expect the new equipment to perform on the line -- is paramount to the success of the equipment integration. Looking to buy new cartoning equipment for your packaging line? Read on for five things to consider before you make the big purchase.

1. Know your cartons (and your overall project) well

Start with the basics: knowing your cartons and the equipment on your line will help you determine which style of cartoning machine you’ll need. You’ll want to work with the OEM and share your cartoning goals. Discuss what upstream equipment will integrate with the cartoning equipment (flow wrapper, vertical bagger, etc.). Also, specify how many sizes will run on the machine, what style of carton (top-load or end-load style), as well as how many lanes are coming in and what type of product you’re cartoning so they can design off that. Consider that cartoning equipment tends to fall into market application segments that dictate their own solutions. Cartoning equipment for pharma/cosmetic, food, and beverage applications are each uniquely optimized to meet the size range, operating speeds, pack configurations, and infeed solutions required for their markets and related subsets.

2. Don’t over-specify your cartoning equipment needs

Be careful not to over-specify for future needs as it will negatively impact the complexity and performance of the machine being purchased. You don’t want to be overly specific or overly vague. When purchasing cartoning equipment, specify how many sizes will run on the machine, but be realistic. For example, some customers will give specs with 100 different sizes, yet they’re only going to run five or six. Should the OEM design a machine for the 100 or the six? Going the route of the 100 will make the project a lot more complex than it needs to be. Acquiring an overly complex machine can prove problematic – you only want your staff to operate what it can understand. On the other hand, keeping the project too simple can limit future growth. Ask yourself if you will need larger packs or multipacks in the future. If the machine only goes between two different sizes, you may need different equipment, and retrofitting can be prohibitively costly. Plan for flexibility and change.

3. Know your desired speeds

Know your desired speed for overall cartons per minute. Also, understand the speed of the equipment feeding into the cartoner. Note that placing the product into the in-feed conveyor's flights, at the required speed, is critical to the efficient operation of the cartoning equipment. Factors like the rigidity of the product being packaged and the speed of upstream equipment impact the overall line speed. A knowledgeable supplier or OEM can help create a tailored solution for you. Innovative suppliers can address pitched or non-pitched product with their cartoning equipment solutions. Product-pitched systems tend to allow for higher operating speeds. Keep in mind that the ability to add filling capacity and adjust speed to match is important when choosing cartoning equipment.

4. Work with a reputable cartoning equipment provider

It is important to work with a reputable, experienced cartoning equipment supplier who takes the time to collaborate with the end user on their current and future needs to ensure the machine will meet their expectations. Who’s providing the material? It can be a benefit to work with a single-source paperboard supplier to avoid finger-pointing if an issue occurs. Involve the OEM with your carton design or redesign whenever possible. Choosing a supplier that can provide cartoning equipment with a lock or glue-style closure gives you the flexibility to choose depending upon the product, package style, and plant needs. For example, lock-closure cartons eliminate the need for glue consumables, thereby reducing costs and maintenance. Glue closure provides greater tamper-evident visibility on the shelf compared to lock closure. Working with a cartoning equipment supplier that offers these choices and has the knowledge to help you choose the best carton and equipment will pay off in the long run.

5. Consider automation

The most efficient cartoning operation will be a fully automated cartoning process, so it is wise to choose a cartoning style to best suit this. If the product you’re cartoning is a single solid product or single bag (such as a single tray of frozen food, or frozen pizza, or even a bag of cookies) those products can be easily fully automated more inexpensively by using an end-load cartoning equipment paired with an automatic product transfer system, such as a "smart belt" infeed or a "bomb door" style drop transfer. However, if there are to be multiple products inside the carton, then a top-load cartoning system is best. Top-load systems typically can be linked to either a product collating-loading system (if the products can be easily oriented to send them into indexing pockets) or a vision guided robotic pick-and-place loading system to handle randomly oriented arriving products. Either way, consider that automated cartoning systems deliver maximum efficiency.

While cartoning equipment tends to fall into market application segments that dictate their own solutions, it’s still important to understand the equipment you intend to purchase, as well as the project in question, to get the most out of the new piece of cartoning equipment. When in doubt, align yourself with a knowledgeable OEM that can help you find the right solution.

Browse companies that provide Cartoning Equipment right here on PMMI ProSource.

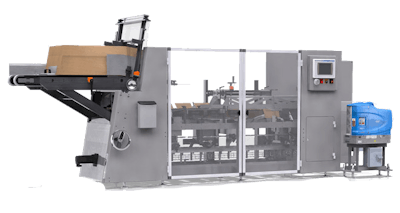

Featured image courtesy of Douglas Machine Inc.