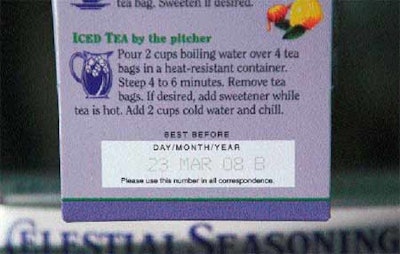

It replaced an embossing coder that wasn’t as reliable as they’d hoped, says Celestial’s Art Osborne, who refers to the laser coder as a maintenance-free unit. David Ziegert says the laser coder helped them increase output by 20% to 25%. Even at that, the unit is only operating at half of its capability, he adds. It marks the cartons with a clear-to-read ‘best before’ date.

Companies in this article