Savvy packaging printing vendors have realized this, and some are beginning to use the Web not just for sales purposes, but to allow customers to proof artwork as it moves through the prepress process.

J.L. Clark (Rockford, IL), a maker and printer of metal boxes, cans and tins, launched earlier this year its Clark Art Network (“CAN”—get it?), which allows its customers to take advantage of such online proofing.

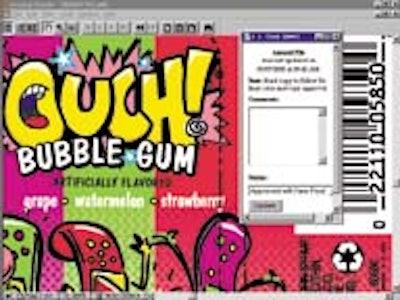

Amurol Confections, a Yorkville, IL-based producer of Ouch® bubble gum for kids, was one of the early users of J.L. Clark’s Internet proofing process when it updated the graphics on that product’s package: a metal tin reminiscent of Band-Aid® adhesive strips. The package is manufactured and printed via offset lithography by J.L. Clark.

The heady name “Clark Art Network” belies the simplicity of the process.

To show Amurol a digital proof of the package graphics, J.L. Clark creates an Adobe PDF version of the artwork and posts it on a secure, password-protected spot on the Internet. Amurol’s Jorjann Howell, packaging graphics design coordinator, then types in a password. The artwork appears right in her Web browser thanks to the Adobe PDF Reader software, which comes standard with today’s Web browsing software.

For the uninitiated, PDF, which stands for Portable Document Format, is a universal format that can be read by any computer running Adobe’s reader software. (It can be freely downloaded from Adobe’s Web site at www.adobe.com). Regardless of whether you are running Windows 95, 98, NT, 2000 or even a Macintosh, a PDF document is virtually assured of appearing to the user in the exact same format as it was created. Users can magnify an image several-hundred percent to inspect the most minute of details without any loss in quality—perfect for magnifying that pesky 5-point type into, say, 5”-H letters that are easily readable on the screen.

PDF is an inspired answer to the problem of sharing complex combinations of graphics and text across time, space and computer platforms.

Eliminates steps

In J.L. Clark’s case, it has begun using CAN to eliminate those intermediate-stage approvals where revisions of expensive color proofs are traditionally sent via overnight courier two or three times until final approvals are granted.

“It eliminates the back-and-forth process,” says Howell. “I just view the proof online and type in any changes that I would like to see.” J.L. Clark is able to implement those changes and then post another PDF, which triggers an e-mail to Howell to take another look, often during the same day.

Since PDF documents are read-only and cannot be modified by the PDF reader software, a separate browser window pops up to allow CAN users to type in any remarks or comments. A drop-down menu can be selected by the user to indicate whether the proof is approved or requires further changes. CAN keeps an electronic “paper trail” of every step of the art change /approval process, noting who requested or made each change and when.

Howell acknowl-edges CAN compressed the back-and-forth process inherent in the prepress process by at least a week. “It was convenient. I didn’t have to get up from what I was doing and go pick up a [proof]. I was able to view and make changes right from my desktop,” says Howell.

J.L. Clark offers CAN as a free, value-added service to its customers. Howell confirms that her company doesn’t pay anything to use it. Apart from an Internet connection, no special software beyond a garden-variety Web browser is required. Amurol actually saves money by not having to incur proofing and delivery charges of multiple color proofs.

Amurol, like J.L. Clark’s other customers, still requires a final proof as a hard copy match print, preferring to rely on CAN more for copy, sizing and positioning. Nevertheless, Howell gives CAN high marks.

“We have used J.L. Clark before, but this is the first time we had used its online proofing system,” Howell says. “I was very impressed with it.”