The total consumption of biodegradable polymers in North America, Europe, and Asia is forecast to grow at an average annual rate of nearly 13% over the five-year period from 2009 to 2014. That’s according to a new study, “Biodegradable Polymers,” from SRI Consulting.The report adds that the single-largest end use for this material will be the “food packaging, dish, and cutlery market,” which it says “will be the major growth driver in the future.”

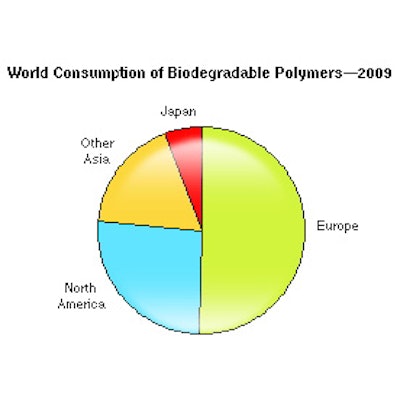

In 2009, demand for biodegradable polymers in North America, Europe, and Asia accounted for most of the global consumption. Despite the economic crisis, which hit the chemical and plastics industry, the market for biodegradable polymers did grow in 2009 in almost all regions. In Europe, the largest global market, growth was in the range of 5% to 10%, depending on products and applications, compared with 2008.

Europe continues to be the largest biodegradable polymers-consuming region, with about half of the global total. Major market drivers for biodegradable polymers in this region include legislation, depleting landfill capacities, pressure from retailers, growing consumer interest in sustainable plastic solutions, fossil oil and gas independence, and the reduction of greenhouse gas emissions.

North American consumption of biodegradable polymers has grown significantly in recent years. According to the study, the following factors have contributed to and will continue to contribute to growth:

• Biodegradable polymers have become more cost-competitive with petroleum-based products

• There has been growing support at the local, state, and federal levels for these products and for addressing needs about solid waste disposal

• There is increasing public awareness regarding the depletion of petroleum-based raw materials

• Large retailers and manufacturing companies desire to develop more sustainable raw material sources as well as to impact global warming

• The properties and processing of biodegradable polymers have improved.

In Japan, there has been some growth in biodegradable polymers use as a result of government and industry promoting their use. The rising prices for petroleum and petroleum-based products have also contributed to the replacement of petroleum-based polymers with biodegradable polymers. However, Japanese consumption of biodegradable polymers has not increased as much as expected.

In Other Asian countries, biodegradable polymer demand is expected to increase greatly in the next several years. In China, high growth will be due to several factors: an increase in production capacity, demand for environmentally friendly products, and the government’s plastic waste control legislation.

Compostability benefits considered

Use of biodegradable polymers continues to grow, even though some of their benefits are viewed as of more longer-term interest. Their greatest impact may be in the future, when infrastructures and systems have improved. For example, in the U.S., it is expected that when there is a large volume of compostable products (driven by their low carbon footprint), then it will make economic and environmental sense to compost and recycle more. In Europe, however, Western European countries have large-scale composting facilities already in place and are composting several million metric tons of source-separated organic waste.

For biodegradable materials, it is generally regarded that the product will degrade into water and carbon dioxide by virtue of a naturally occurring organism, such as microorganisms. Some industry sources have offered the term compostable in place of biodegradable. To be considered compostable, three criteria must be met: biodegradation—it has to break down into carbon dioxide, water and biomass at the same rate as cellulose; disintegration—the plastic must become indistinguishable in the compost; and nontoxicity. Most international standards (such as ISO 17088) require at least a 60% biodegradation of a product within 180 days, along with other factors, in order to be called compostable.

According to the report, biodegradable polymers are part of the larger biopolymers market. The industry defines biopolymers, or bioplastics, as polymers that are either bio-based or biodegradable (some materials like NatureWorks’ Ingeo™ polylactic acid are both). Some bio-based products are not necessarily biodegradable (e.g., polyethylene based on ethanol), while some biodegradable products are actually made from petroleum-based products (e.g., polycaprolactone).

The issue between bio-based and biodegradable materials has continued to attract attention worldwide. In Japan, the idea of bio-based renewability is becoming more important relative to biodegradable materials. In the U.S. and Europe, industry sources comment that the idea of bio-based or “where it comes from” versus biodegradable, or “where it goes” is currently driving or will drive the overall biopolymers market in the future.

Bio-based products have gained support as a result of the current focus on climate change and the low carbon footprint that results, as well as legislation (at the national and international levels), cap and trade issues, etc.