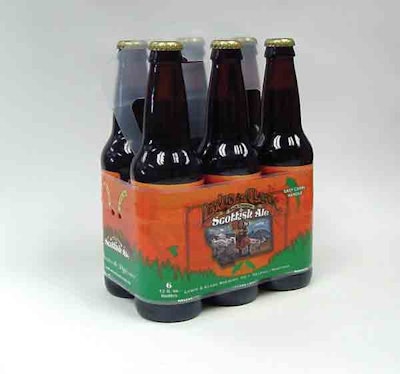

“This unique and exciting package is helping us launch our Miner’s Gold brand quicker and more economically than with paperboard carriers,” says brewery owner Max Pigman. “We also know that our customers appreciate the environmental benefits of the new packaging. It’s a minimal design that generates less waste than paperboard carriers.”

The film makes the pack waterproof and capable of direct chilling in ice. Pigman notes that the format permits greater production flexibility because Lewis and Clark can use generic cases to receive the bottles. Then the company packs as needed versus storing preprinted, product-specific paperboard carriers.