This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The 4in X 7in pressure sensitive label is coated with adhesive on the leading 3in of the label; the remaining 4in of the label has no adhesive. The challenge was to automatically apply the leading 2in adhesive portion of the label on the top of the pallet stack and fold the remaining 1in of the adhesive to the upper side of the pallet. This process resulted in the label only being affixed to the product banding frame and at no time would adhesive come into contact with the bottles.

The pallets can range in height from 6 feet to 10 feet and the distance from the printer applicator to the pallet ranging from 36 inches to 56 inches.

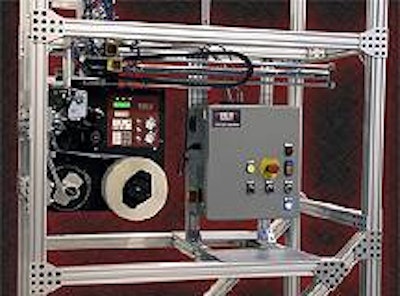

FOX IV designed and manufactured a complete labeling station over 12 feet in height - consisting of an Intermec based label printer applicator, a custom sensor system to accurately locate the top edge of the pallet at varying distances and an application system capable of applying a label to randomly sized pallets.

After printing the unique label and confirming the pallets presence the applicator arm automatically targets the top of the pallet. The adhesive portion of the label is applied to the top of the pallet, and the applicator arm automatically folds the remaining five inches of the label to the side of the pallet.

The turnkey system supplied by FOX IV Technologies, Inc. consists of multiple FOX IV labeling stations networked and integrated into the customers Ethernet based warehouse management system. FOX IV's software receives production requirements for each production line from the customer's WMS. FOX IV::-trade-::s software automatically downloads a unique label to the specified printer applicator, keeps track of the pallet quantities, and alerts the operator when production is complete.

Operators are alerted to any fault warnings via a light tower. The customer can monitor the printer status on their network; thereby providing them with enterprise wide system monitoring.

FOX IV's Model 4400 Uniwall label printer applicator was the basis for this application. The Model 4400 Uniwall integrates the Intermec PX4i into the centerwall of the label printer applicator. This FOX IV model label printer applicator was selected because of the customer's existing commitment to Intermec. The communication interface and the data stream to the FOX IV Model 4400 Uniwall label printer applicator are the same as to the Intermec Model 4Xi printers.