Companies in this article

Videos from Universal Labeling Systems, Inc.

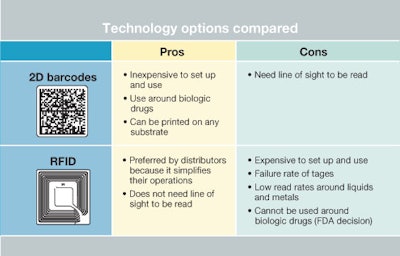

Catalent Pharma Solution’s Akan Oton provides a contract manufacturer/packager’s perspective on serialization, authentication, and track-and-trace technologies in pharmaceutical distribution.