This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

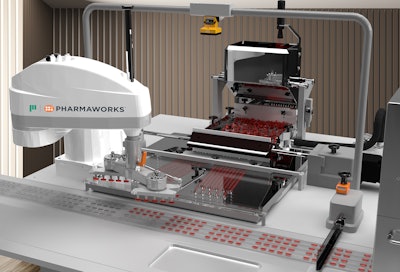

Pharmaworks’ compact pick and place system can now feed even difficult-to-handle solid-dose pharmaceuticals and nutraceuticals such as fragile, unusually shaped, and orally dissolving products. The enhanced FA1 achieves new levels of gentle handling, virtually eliminates particulates from reaching the blister web and accurately positions products within the blister cavities, all while simplifying operations.

Featuring a cGMP design and running up to 80 cycles/min per minute, the FA1 can be integrated with small- to medium-format size blister machines, including the TF1 and TF2 series from Pharmaworks as well as blister machines from other suppliers.

Previously, the FA1 relied on gravity to move product on feed tracks set at a 45-degree angle. Now, the enhanced FA1 can convey even challenging products more gently with fully-horizontal vibratory feed tracks. By leveraging vibratory motion, the new system has also eliminated the chance of “shingling,” in which one solid dose gets jammed under another and creates a blockage. Once products have been conveyed to the end of the feed track, the FA1’s servo-driven, pick and place vacuum head positions an array of solid doses, correctly oriented, into their blister cavities.

Ideal for smaller batches, the enhanced FA1 can change over to a new format in as little as three minutes with no tools required and minimal change parts. Product recipes can be accessed via its PC-based color touchscreen HMI. Compared to tube feeders, the FA1 offers simpler and more affordable change parts and tooling. Workers can easily view and access the entire feeding process for line clearance and sanitation as well as maintenance.

To feed multiple types of products into a single index, such as a nighttime/daytime cold medicine combination pack, the enhanced FA1 can be equipped with two or more paddle boxes and bulk hopper systems.