This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

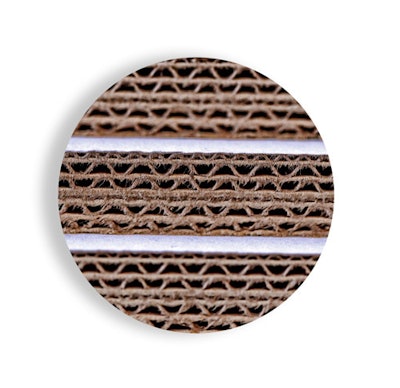

The result is a container that increases top to bottom strength, reduces bottom sag, and at the same time is more sustainable. A further benefit is that the use of microflutes virtually eliminates flute lines. This results in a superior printing surface, increasing the appeal of the container. Made of lightweight liners and mediums, the Tri-Wall is used for all strawberry, tree fruit and grape trays, as well as the body of bliss boxes. Tri-Wall Times Two is Maxco’s 6-ply product. Two Tri-Wall boards are laminated together and cut into bliss ends using water jet technology. Maxco has replaced all quad-wall ends with Tri-Wall Times Two bliss ends this year.

These new containers are the latest step forward in Maxco’s continuing mission to manufacture a produce box that increases top to bottom strength, while at the same time reducing bottom sag of fresh produce containers. This product is also in line with the company’s goal of creating a greener box, with the new container being 100% recyclable while using less labor, materials and energy in production, ultimately increasing sustainability.

Installing a third single facer and a new glue station, as well as some minor additions to the corrugator, allowed Maxco put the new Microflute Tri-Wall containers into production earlier this year. With so many positive effects as a result of this new product, Maxco is replacing Double Wall trays and wraps with Triple Wall and all quad-wall ends with 6-ply ends in an effort to:

• Increase top to bottom performance

• Reduce bottom sag

• Increase printability using Microflutes on the exterior of container

• Increase sustainability and produce a greener container

• Reduce energy consumption

• Reduce starch consumption

• Reduce paper consumption

• Reduce freight costs from the paper mill to the plant

• Reduce freight costs from the plant to customers

• Maintain grower costs

These new containers are the latest step forward in Maxco’s continuing mission to manufacture a produce box that increases top to bottom strength, while at the same time reducing bottom sag of fresh produce containers. This product is also in line with the company’s goal of creating a greener box, with the new container being 100% recyclable while using less labor, materials and energy in production, ultimately increasing sustainability.

Installing a third single facer and a new glue station, as well as some minor additions to the corrugator, allowed Maxco put the new Microflute Tri-Wall containers into production earlier this year. With so many positive effects as a result of this new product, Maxco is replacing Double Wall trays and wraps with Triple Wall and all quad-wall ends with 6-ply ends in an effort to:

• Increase top to bottom performance

• Reduce bottom sag

• Increase printability using Microflutes on the exterior of container

• Increase sustainability and produce a greener container

• Reduce energy consumption

• Reduce starch consumption

• Reduce paper consumption

• Reduce freight costs from the paper mill to the plant

• Reduce freight costs from the plant to customers

• Maintain grower costs

Companies in this article