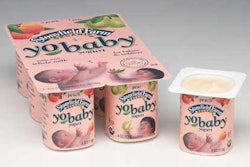

A custom multilayer blow-molded jar is now giving customers of Signature Fruit Co., Modesto, CA, a new look at peaches, apricots, and fruit medley. That’s because the 63-mm wide-mouth jar is molded of a clarified polypropylene to yield as clear a package as possible.

The jars were developed by Signature and Graham Packaging over many months of testing. The key requirement that needed to be met was that the plastic jar had to be able to withstand post-fill pasteurization, says Don Jepson, director of engineering at Signature (formerly known as Tri-Valley Growers).

“Our process is what we call ‘warm-fill’ and then ‘post-sterilization,’” Jepson says. “So the jars needed to be able to withstand the cook process and that resulted in going to polypropylene. It’s a polypropylene coextruded with an oxygen barrier and also a barrier to ultraviolet light.”

Graham uses a resin master batch that’s blended with a clarifier to make the jar as transparent as possible, according to Jay Arnold, spokesman for Graham Packaging. “A lot of the newer polypropylenes have new clarifiers added.” The jars weigh 54 g and comprise seven layers, including a layer of ethylene vinyl alcohol copolymer for its oxygen-barrier properties, Arnold points out. “We had to add some gram weight to the jar so that it could withstand the pasteurization,” he says.

“Clarity was an issue that we worked on with Graham. We wanted it to look as clear as a PET bottle, but they can only work with resins that can withstand the processing,” Jepson adds.

In addition, the jar is sealed with a PP screw cap with a steel insert, much like old canning jars, he adds. The cap is from Crown Cork and Seal and it’s called the Ideal 63-mm finish with four-lead lug. It also incorporates a tamper-evident breakaway band. “We did about six months of pilot lab work to find a system that would provide adequate seal integrity and process performance,” Jepson says.

Once Graham and Signature found a container material that would work, the fruit packer extensively tested all components. Jepson confirms that testing was performed for almost a year. The bottle is decorated by a wraparound oriented polypropylene label that was designed by Nishihara-Wilkinson and converted by Fort Dearborn. The label is 75-ga PP that’s flexo-printed in nine colors and overlaminated with a 48-ga clear PP. It’s applied from rollstock on a new applicator from Trine, one of the new machines in Signature Fruit’s packaging line.

Adding value

Signature Fruit sees the new plastic jar as providing the company with a whole new line of products under its Libby’s licensed brand name, according to Kathy Sheldon, Signature’s vice president of marketing.

“This is not a replacement container for us,” she says. “This line is targeted to a different demographic than glass jars. Glass-packed fruits tend to be rather pricey, and they’re not exactly user-friendly for households with children. So, this line is a mid-range product, priced between cans and glass jars.” The 24.5-oz jars retail for $1.99 to $2.49.

“We decided to market the products under the Libby’s brand, so we selected our best-selling items, like peaches and fruit medley, for this container,” Sheldon continues. “The fruit medley is a bit different from a conventional fruit cocktail; it’s more of a fruit salad. Typically, we made this product only for foodservice customers in the past. So we feel these are premium products that we developed for this upscale packaging.”

The label graphics included a new repeating brandmark for the Libby’s name, according to Ron Wilkinson, the designer at Nishihara-Wilkinson. “But we wanted to leave most of the label clear to let the fruit show through.”

Front panel violator

A violator on the front-panel printing calls attention to “Goodness from California,” which is also repeated in a stripe at the bottom of the front panel. This reinforces, Sheldon says, that these fruits are California-grown and -processed. “We think there really is a quality difference.”

Another label panel calls attention to the resealable, easy-to-pour jar.

The line was introduced shortly before Thanksgiving 2003, although Sheldon points out that few retailers had it on shelf for the holiday. Along with the Libby’s brand that Signature Fruit licenses for deciduous fruits, the company expects to use the jar for store brands as well.

“We’re in label development with a number of store-brand customers now,” Sheldon says. “The level of interest we’ve had in these products and package has been overwhelming. The container has been very well received. So much so, that any new products we develop will probably be packed in this jar.”

Graham will also watch the results of the new container. “We’re curious to see how this container will do in the market,” Arnold says. “After all, this is our first wide-mouth container in polypropylene.”