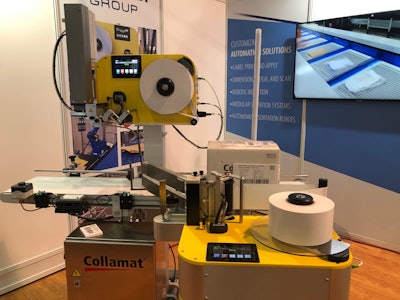

Offering “A Green Revolution,” Collamat’s fourth-generation Linerfree print-and-apply direct thermal label printers have been designed to accommodate linerless labels, resulting in both cost and environmental advantages. “Essentially you can have twice as many labels on a roll because we don’t occupy the label roll with the release liner,” explained Torben Zerlang, sales executive with Switzerland-based Collamat, at the company’s PACK EXPO Las Vegas booth. “That means you can cut down on the number of label rolls you need, and your inventory and transportation costs are less.” This also results in longer uptime per roll.

According to the company Collamat’s Linerfree contributes to four of the United Nations Global Compact Sustainable Development Goals (SDGs), including #9, Industry, Innovation and Infrastructure; #12, Responsible Consumption and Production; #13, Climate Action; and #15, Life on Land. Pointed out Zerlang, the label industry is responsible for 40 billion square meters of backing paper annually, with 50% to 60% of that material going to landfills.

“In all honesty, the backing paper is very expensive to recycle,” Zerlang said. “So a lot of it goes to landfills. And someone has to haul it, take it to the garbage bin, and then haul it from there to the landfill or wherever it goes. There’s a cost to that money-wise, but also environmentally. With Linerfree, there is nothing that has to be taken away and disposed of because we’re using the entire label.”

Linerfree is available in a wipe-on and tamp-on version, with the transfer components designed with a surface pattern that resists adherence by the label material. Both models can produce labels of variable length, as cutting is done on-the-fly. This is especially helpful when applying different formats for shipping labels, when the information on each label is different, or a different length format is needed on the same run.

Zerlang also pointed out that the Linerfree labeler is easy to change over and maintain, with all the wear parts, including the print head, the platen roller, and the knife, able to be exchanged without tools. Collamat can also supervise the machinery remotely for troubleshooting.

Specifications of the machine include a 12-in. label roll dia, a 2- to 4-in. label width capability, and a maximum label roll length of 2,460 ft. The stepper motor-driven unit uses a 4-in. Zebra direct thermal printer module and can print in 203-, 300-, and 600-dpi resolution. PW