Our survey on p. 64 documents the pitfalls packagers have experienced in collecting data, converting it into knowledge, and acting on it. But there’s no question that the payoff—boosting line efficiencies and correcting quality problems early—is too great to ignore. In the pages that follow, we present several successful data acquisition implementations.

OEE drives Kraft’s machine performance

User: Kraft Foods

Application: Collecting plant-floor data to calculate Overall Equipment Effectiveness (OEE) as a measure of packaging machinery reliability.

Data collected: A wide variety of process and production data on nearly 500 packaging lines in 48 plants in North America.

Benefits: Measure asset utilization and performance across multiple

facilities. Help determine whether to spend on improvements or capital

investments in new machinery. Find ways to increase productivity or eliminate common downtime causes. Provide line operators with actionable data in real time to help them make better decisions.

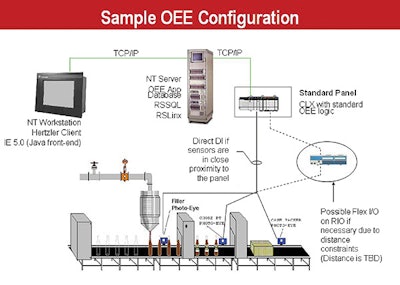

Technology: A full range of Rockwell Automation hardware, software, and technology consulting services.

How it works: Kraft uses OEE as a standardized way of measuring each packaging machine’s performance and impact on the plant’s overall throughput or downtime. Reports show actual performance versus targets.

Who uses data: Line operators, team leaders, plant managers, and senior corporate management with responsibilities in product weight control, statistical process control, finance, maintenance, and materials management.

Networks: A full architecture of integrated networks spanning multiple packaging lines, plants, and corporate sites.

Quote: “OEE gives us the data to measure reliability, and a more reliable line costs us less in materials and labor to run.” —Frank Meegan, senior vp, operations, Kraft Foods North America.

Source: Client Case History commissioned by Rockwell Automation and prepared by ARC Advisory Group, January 2003.