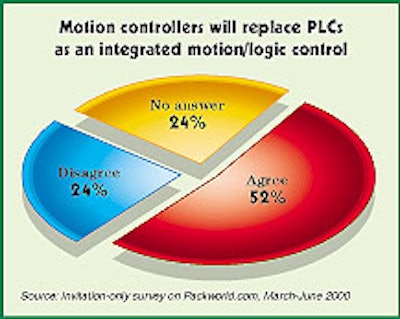

More than 70% of all respondents to a recent survey said that motion and logic should be integrated into the same control platform on modern packaging equipment. Further, another 52% believed that the motion controller will replace the PLC for packaging equipment controlled by a single controller that handles motion and logic. Funded by Rexroth Indramat (Hoffman Estates, IL), the survey was conducted for the Motion for Packaging Working Group of the Open Modular Architecture Controls (OMAC) users group. Conducted via the Packworld.com Web site March through June 2000, the invitation-only survey consisted of mostly packaging end users, though it included some machinery builders. While it’s not a statistical representation of the industry as a whole, the survey does give a back-of-the-napkin sketch of the way many packaging end users view motion control and networking issues related to packaging machinery. The survey found that Ethernet, a common networking protocol, seems to dominate packaging machine networking. Two-thirds of respondents are planning on Ethernet for the interface from machine controllers to supervisory/enterprise systems. And almost as many (60%) plan on using Ethernet for machine-to-machine (also known as peer-to-peer) networking. Nearly a third are using it already. When asked which protocol would be implemented over Ethernet, the winner was hyper-text transfer protocol (HTTP), the same protocol used on the World Wide Web, with more than a 40% response. (For industrial networking, a secondary protocol is typically required on top of Ethernet.) Next came DeviceNet (35%), ControlNet (26%), with the remainder splintered among a number of other protocols. Surprisingly, 44% of respondents are planning on using Ethernet for an I/O network, sometimes referred to as a fieldbus or device-level network, within a packaging machine.