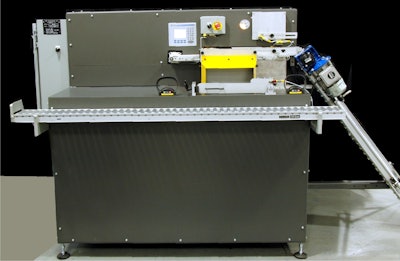

The compact system provides an automated infeed and collation process that can handle a number of products. Once the product has been collated into the correct pack pattern, the operator manually places an erected carton onto the loading area. Finger-safe hand controls activate the loading process, and a mechanical pusher system pushes the collated product into the case. The case is manually removed from the loading position and conveyed to a case closing area. Case closure may be done manually, or the SA-5 may be equipped with optional glue or tape closing stations to further automate the process.

A basic operator control panel offers an Allen-Bradley PanelViewPlus 400 HMI that facilitates size changeover and system troubleshooting as well as LED indicators to show the following: System running, box present at the loading area, pack pattern ready to be loaded, and system fault. The compact footprint offers a minimum footprint of 53-in. x 107-in. (actual size varies based on the infeed requirements). The machine may be ordered for either left-to-right or right-to-left operation. An optional starwheel assembly with frame, motor, drive and clutch may be ordered to facilitate the loading and collation of round cylindrical products. The Model SA-5 Semi Automatic Case Packer features one complete set of size parts, 120 Volts AC operation, infeed and discharge conveyors with controls, and UL certified panel.