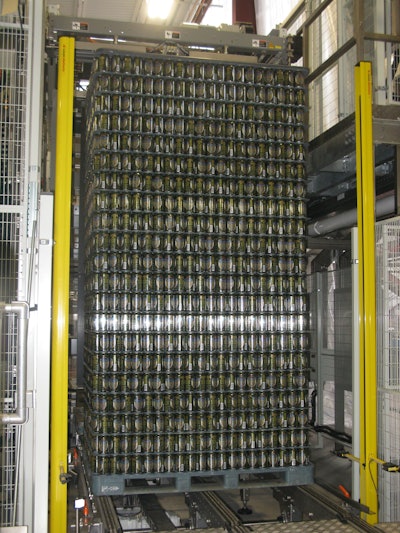

In a new canning line at Founders Brewing in Grand Rapids, MI, a Krones Pressant high-level-discharge depalletizer is the first machine in the line. An operator loads pallets of cans, supplied by Ball, into its infeed conveyor and cuts the plastic strapping. The pallet then moves into the hoist bin. Up above, the top frame is automatically removed as well as the tier sheets that separate each layer. Then the cans are swept one layer at a time into a long stretch of conveyor that makes a U-turn and eventually single files them so they can proceed down an incline conveyor and into the filler. One notable component on this entire conveyor stretch from depalletizer to filler is that it’s covered by clear plexiglass. “We have, of course, an ionized air rinser ahead of the filler, but we wanted to add this extra layer of protection to be extra sure nothing drops into a can,” says Packaging Manager Matt Sutton.