The use of robots for packaging applications is on the rise. According to a report from PMMI (see www.pmmi.org/research), The Association for Packaging and Processing Technologies (www.pmmi.org), since 2008, the number of packagers surveyed in the report that employ robots has grown from one out of five manufacturing locations to three out of four. This includes applications in food and beverage, pharmaceutical, medical device, and consumer packaged goods (defined by PMMI as non-food and beverage) (Source: 2014 Trends in Robotics Market Assessment, www.pmmi.org/research).

Among the hoped-for benefits of adding robotics, according to the survey, end users are looking for reduced labor (67%), reliable product quality (66%), operator safety (57%), throughput efficiency (52%), operational flexibility (31%), reduced operational costs (15%), and a smaller footprint (13%).

In part one of Packaging World’s annual Special Report on Robotics & Automation, four food and beverage packagers demonstrate how robots are meeting these expectations in their plants. See part two of the special report in the September 2015 issue.

Robotic palletizer’s flexibility is key for beverage bottler

Clinton’s Ditch Cooperative Co., Inc. was born in 1968 in Cicero, NY, as an independent bottler of Pepsi-Cola. Today the company bottles and cans approximately 22 million cases/yr of carbonated soft drinks, seltzers, energy drinks, and purified water, distributing them to much of New York State, the mid-Atlantic region, and throughout Canada.

In 2010, Clinton’s Ditch recognized that its can business was slowly decreasing to the point where its smaller can line was sitting unused most of the time. Says Tom Millert, Plant Manager at Clinton’s Ditch, “We started looking for other things to do with it—rip it out, make it a glass line, etc.”

In 2011 and 2012, as new beverage can sizes became increasingly popular, Clinton’s Ditch decided to invest in the unused line and turn it into one capable of filling a range of can sizes, including 7.5-oz, 8-oz, 12-oz standard, 12-oz sleek, 16-oz, and 24-oz cans. The “flex can line initiative” included the installation of a number of new machines, changeparts, and retrofits. Scrapping two 36-year-old conventional palletizers, Clinton’s Ditch purchased a new high-speed robotic case palletizer, the Model LP-7500 from Conveyor & Automation Technologies, Inc., which installed the system in April 2014.

“We had two old 1978 palletizers that could not be modified to handle the variety of packs we needed to run,” says Millert. “Packs they could run were not handled gently or efficiently, and consequently, we had package and container damage and breakage. We also wanted a machine that would allow us to easily add new container, pack, or pallet sizes for a reasonable cost.”

With the new flex can line, filled cans can be sent to any one of four secondary packaging machines to be packed in cartons, trays, shrink packs, or Hi-Cone ring packs, all of which are handled by the new palletizer.

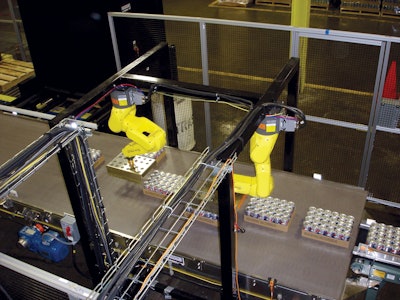

The Model LP-7500 comprises three Fanuc robots: two LR Mate 200iD six-axis row-placement robots and one palletizing robot, the M-410iC. During operation of the line, finished packs travel on a full-case conveyor approximately 550 ft from Clinton’s Ditch front production area to another building where its palletizing area is housed. Here, the packs travel down an incline to the 48-in.-high robotic palletizer infeed, where cases are metered, with at least a 3-in. gap, into the layer forming section of the system. Next, the two LR Mate 200iD robots gently turn and/or position each package in one of three zones on the conveyor according to an HMI screen-selected pallet pattern. Packages then travel in their appropriate sequence and position to the layer accumulation area, where the layer is formed, ready for palletizing.

The second robot, the M-410iC, with a payload of 690 lb, is fitted with a custom servo-driven end-of-arm layer pick tool with an undercarriage that picks, squares, and places an entire layer of cases on the pallet at one time. The tool allows for any layer that can be held on a pallet up to 40 x 48 in. to be palletized with the same tool. At Clinton’s Ditch, pallet sizes include 36 x 43.5 in., 36 x 42 in., and 40 x 48 in.

According to Gus Sarikas, VP of Sales at Conveyor & Automation, one of the system’s greatest benefits to Clinton's Ditch is its flexibility and easy changeover—making it a fitting selection for the flex can line. “It’s a really quick changeout,” he says. “The operator selects the recipe they are going to run, changes the end-of-arm tools on the row placement robots—a task that takes less than five minutes—and adjusts one infeed rail, and the system is ready to run a new product.

“The reason this was key for Clinton’s Ditch was their range of secondary package sizes, which include six-, eight-, 12-, and 24-count packs. They’ve got variable pack heights, variable can diameters, and variable case sizes. They also have variable pallet dimensions. To be able to accommodate all that and do a quick changeout—because they probably run four to six products in the course of a day—was vital.”

Currently, Conveyor & Automation has programmed 11 pallet patterns for Clinton’s Ditch and has supplied the corresponding 22 EOAT tools for the two row-placement robots.

Since converting its small can line to the flex line, Clinton’s Ditch's output has grown substantially from 4.3 million cases of cans in 2012 to an estimated 8.8 million in 2015, a volume that the new robotic palletizing system is well equipped to handle. See a video of the Model LP-7500 at pwgo.to/1666.

Robots facilitate rebirth of pasta producer

For Italian pasta maker Pastificio Ghigi, automation provided the path to its rebirth and return to competitiveness after the financial crisis of 2007. Founded in 1870 in the town of Rimini in Morciano di Romagna, Ghigi was for 130 years a major buyer of durum wheat, supporting local Italian wheat producers and other suppliers of raw materials for pasta. At its peak, Ghigi employed 400 workers and produced 220 tons pasta/day. But in the two decades preceding the recession, Ghigi lost its footing in an increasingly competitive market and was forced into bankruptcy, shuttering its facility in 2008.

Not long after the plant closure, the Agricultural Consortium of Forli-Cesena-Rimini, recognizing the important role Ghigi had played in the local economy, reopened the company in San Clemente, Italy, to help reinvigorate and develop the Emilia-Romagna region. The new plant covers approximately 330,000 sq ft and is noted for its high degree of automation; in fact, virtually every activity in the plant is automated. Says Bartolo Aprea, Ghigi Project Manager – R&S + Innovation & Information Technology, “Automation is the only way to be truly competitive in the market.”

To supply and integrate its eight packaging lines, Ghigi worked closely with Tiber Pack. Ghigi’s main system requirements—particularly for its end-of-line machines—were flexibility to carefully handle a range of product and package types, and reliability to keep pace with its 750,000-ton/yr dry pasta capacity. To this end, Tiber Pack installed four Smart PAL 180-3.1 palletizing robots from Comau.

The Smart PAL 180-3.1 is a four-axis robot with a 180-kg payload and a 3,100-mm reach. At Ghigi, each of the robots handles product coming off two packaging lines. Case sizes range from approximately 5 1∕8 x 10 x 10 in. to 271∕2 x 153∕4 x 12 in. in weights from 7.7 lb to 86 lb.

According to Aprea, the positioning of the cases on the pallet is vital. Ghigi exports 90% of its product, so cases must be placed carefully and securely on the pallet to maintain quality during transport. “Our packaging changes in terms of shape and weight depending on several factors, including the type of pasta it contains, the type of box used (some boxes use less corrugated and have special shapes), and the country to which the products will be sent,” he says. “This means that we cannot allow mistakes during the packaging and palletizing phases.

“These variables require that the robot is capable of handling different boxes, in different positions, of different weights, and with a different sensitivity depending on the movements to be made. Furthermore, the robots must be able to absorb, in terms of capacity and sensitivity, the inaccuracies that may result from the pasta shaping, which over time can occasionally produce pasta of slightly different weights and dimensions compared to the standards. The Comau robots handle these activities and these variables without exception.”

To delicately handle the cases of pasta, the Smart PAL is equipped with a gripper end effector that uses fingers to grip the case. Changeover is quick and easy, allowing Ghigi to meet its high production rates.

According to Aprea, installation of the Comau robots has not only brought positive benefits to Ghigi itself, but also to its workers and to the producers of raw materials who make up the consortium. “Automation has allowed us to provide high-level training for the operators who work with us,” he says. “The people who work in our factory are not just workers; they are skilled employees able to lead automated lines as their responsibilities have grown continuously over time.

“In addition, our production rates, the increase in productivity, our results and efficiency at different stages, the reduction of costs related to waste, and the quality of our products—which is guaranteed by the sophisticated controls at the start of the line—allow us to significantly reduce our production costs and, as a result, we have more resources to invest in raw materials. In this way, Ghigi has been able to spread the value that the plant is able to generate across the entire value chain.”

Satisfaction spurs repeat robot orders

For the past decade, Pacific Foods of Oregon has continually added to its installed base of palletizing robots as its offerings in the natural and organic foods category have grown in number and in popularity. Since it was founded in 1987, the company has seen double-digit growth virtually every year. It currently produces more than 300 million pounds of organic broths, soups, and chowder annually. In addition, it also delivers a range of other shelf-stable products, including “soup starters,” non-dairy beverages such as almond and hazelnut milk, and ready-to-eat meals, sides, and sauces. In all, the company manufactures more than 200 SKUs on a 24/7 schedule.

To preserve the freshness of its natural ingredients, Pacific Foods uses aseptic and retort cartons, with its Tualatin, OR, facility equipped with nine aseptic and two retort lines. In 2006, the company purchased its first robotic palletizer, the A1600 from Columbia/Okura, to handle palletizing, with various case patterns, from four of its production lines. Over the years, Pacific Foods has installed four more of the same model robot, and is looking to install a sixth at year-end 2015.

Explains Gabriel Vizireanu, Director of Engineering for Pacific Foods, “Some of the robots successfully replaced a conventional palletizer, while some were purchased as an answer to our palletizing needs generated by our growth.”

One of the company’s requirements for a robotic palletizer was ease of use, explains Vizireanu. “The lifetime of these machines is 15 to 20 years,” he says. “We had to ensure that the robot would be relatively simple and could be operated easily, so we wouldn’t increase the complexity of our process more than necessary.”

Space was another issue, he says: “Real estate is at a premium, especially when you are located in the middle of a city, as we are. Minimizing the footprint while optimizing the pedestrian and forklift flow were critical requirements of this project.”

Pacific Foods also needed a solution that would be flexible enough to handle new formats as it continued its tradition of innovation to improve its packaging and reduce its carbon footprint.

Columbia’s A1600 is a compact four-axis robot capable of handling up to four production lines at one time. An operating screen, with detailed graphics and easy navigation tools, allows operators access to 50 standard pallet patterns created with advanced software. Operators can also program custom patterns via a simple off-line process or through the operating screen.

At Pacific Foods the robots are used to palletize its cases of product onto finished goods pallets. Explains Vizireanu, “We load several magazines with pallets, pallet pads, and tie sheets. Multiple conveyor lines bring in cases of product to the robot. Based on a specific recipe for a specific SKU, the robot dispenses an empty pallet from the pallet stack, places a protective pallet pad on the top of the empty pallet, and then adds several layers of cases.”

The robot uses lateral compression, with a clamp-style end effector, to grasp and lift a row of cases. The A1600, with a payload capacity of 310 lb, easily handles the weight of Pacific Foods’ cases, which Vizireanu says are “less than half the weight the robot arm is capable of moving around.” He adds that each robot typically handles two production lines, with the palletizer operating at an average rate of 20 to 25 cases/min—depending on the packaging format—at 75% capacity.

“We enjoy working together with Columbia/Okura and their partners to bring robotic solutions to our operations,” Vizireanu concludes. “Although Columbia/Okura has other types of robots, this specific model fits elegantly with our production lines.”

Custom solution minimizes damage of delicate snacks

When packaging such delicate snackfoods as corn or rice cakes, every step in the process adds risk of damage to the product. That’s why in February 2015, SanoRice—the largest corn/rice cake producer in Europe—added a new wraparound case packer with a customized robot and end effector at its plant in Veenendaal, The Netherlands, to minimize product handling.

With its existing case-packing equipment, rolls of film-wrapped rice cakes were conveyed to the case packer and were turned from a horizontal to a vertical position by means of a belt transport system. Then, while in a vertical position, the rolls were pushed into rows until a complete case load was assembled. From there, the full configuration was brought to the case by means of a pusher system. To eliminate these steps, SanoRice worked with equipment supplier BluePrint Automation, which in the past had supplied the company with more than 15 standard case packers.

Other requirements for the system included a changeover time of less than five minutes, the ability to handle different wraparound case or tray configurations, including 2x3, 3x3, 3x4, 4x4, etc., and increased speed, explains BPA Sales Director, Netherlands, Ed Mets.

The solution comprised a standard wraparound case packer designed specifically for the food industry, with a stainless steel frame and automated five-minute changeover, integrated with a BPA Delta-style robot with a special suction end effector. “Combining a case packer with automatic changeover and a Delta robot, we were able to reach maximum flexibility,” says Mets.

With the new system, rolls of product are carried horizontally on an infeed conveyor to the case packer, where they are presented under the head of the robot. The robot takes one complete row of the pattern, lifts it from the infeed conveyor, and moves it toward the open case. While in transit, the robot head rotates 90 deg, turning the rolls vertically. They are then placed in this position into the case, row by row, until the case is filled and conveyed to the closing station.

Automated changeover from one case size to another is accomplished through the use of seven set points. “We are using motorized spindles with pre-settings in the program,” explains Mets. “So you can choose a recipe, and the machine will change over automatically.”

Providing product and package flexibility, the system handles case sizes from approximately 10.6 x 7 x 6 in. (for a 3x2 configuration) to 14 x 10.6 x 6 in. (4x3), and 90-mm-dia rolls in lengths from 150 to 250 mm. Products can be packed in low or high trays, or in full wraparound cases. The case packer operates at a speed of 80 rolls/min, or 13 cases/min—a 12% increase in speed versus SanoRice’s previous process. According to Mets, the new system also uses less floor space, provides more than 99% efficiency, and is easier to operate than the company’s standard case-packing systems. The company has been so satisfied with the solution, that it has ordered a second system from BPA.