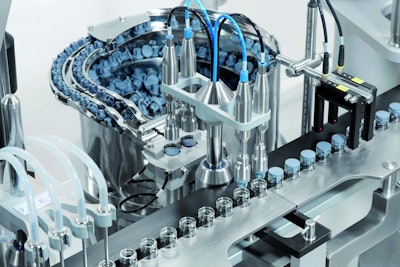

NJM Packaging introduces the Dara SX-300-Lyo aseptic filling and stoppering machine for lyophilized products in vials. The system can be equipped with stainless steel or ceramic rotary piston pumps or peristaltic pumps that employ “single-use” tubing. Featuring fully servo-driven automation and a compact footprint, the SX-300-Lyo offers accurate filling and precise stoppering as well as low maintenance, fast and easy changeovers, and simple setup for adding new vial sizes.

Suitable for suspensions, vaccines, and cellular tissue, the Dara SX-300-Lyo aseptically fills glass or plastic vials with volumes from 1 to 100 mL. It inserts rubber stoppers halfway into the vials for lyophilization.

The SX-300-Lyo can be configured with rotary piston pumps or peristaltic pumps, with one or several filling heads and simple or multiple stoppering stations to achieve throughputs of up to 7,200 vials/hr in a compact footprint. The linear, intermittent-motion SX-300-Lyo is only 70 in. long and 30 in. wide. The rotary piston pumps offer ±0.5% accuracy, and the peristaltic pumps offer ±1% accuracy. The system can be changed over to handle a new product in 15 min., with no tools required.

For sterile or cleanroom applications, the SX-300-Lyo can be equipped with a laminar air flow (LAF), open or closed restricted access barrier system (oRABS/cRABS), or a high-containment isolator system. Optional clean-in-place (CIP), sterilization-in-place (SIP), or gas flushing are also available.

Ancillary equipment, such as automatic or manual denesting units, adapts this machine to any ready-to-fill vials. Trays of sterile vials can be manually fed to the SX-300-Lyo, or the system can be integrated with an upstream vial washer and depyrogenation tunnel for continuous automated feeding. An integrated rotary table single-files vials for presentation to the filling heads. Bags of stoppers are loaded into a vibratory hopper/circular feeder that delivers stoppers to a pneumatic pick-and-place station for insertion into the vials. Filled and stoppered vials are directed to output trays for manual unloading, or they can be integrated with downstream equipment to automatically transport trays to the lyophilization chamber.

Users can program the SX-300-Lyo to fill with nozzles lowered to the bottom of the vials, halfway up, or from above to meet the needs of each product. The system features a no bottle−no fill−no stopper safety device. Inspection stations detect fill levels, missing stoppers, and raised stoppers and trigger an automatic reject to remove out-of-tolerance vials. The system can be equipped with a checkweigher for 100% weight control or a statistical weighing mechanism. An optional particulate counter further ensures final product quality.

Filling vials from 1 to 100 mL, the SX-300-Lyo handles stoppers from 13 to 30 mm in size. A system with a single stopper station accommodates vials up to 2.1 in. in dia and 4.3 in. in height. A double station system accommodates vials up to 1 in. in dia and 2.4 in. in height.

Partially or fully servo-driven, depending on the specific configuration, the SX-300-Lyo offers repeatable performance, low maintenance, simple troubleshooting, fast changeovers, and easy adaptability to future applications and new package formats, such as adding new vial sizes. An Allen-Bradley PLC controls machine functions, and an Allen-Bradley color touchscreen presents a simple and unique user interface that includes dosing or weighing scales. All production parameters can be programmed into the PLC, including dosing volumes, dosing speeds, kinematics of the filling system, adjustment of automatic feeders, and output.

The SX-300-Lyo can be equipped with data-recording software to export the production data in compliance with 21 CFR Part 11. Designed in compliance with cGMP, the SX-300-Lyo features 304 stainless-steel frame and electro-polished 316 stainless-steel product contact parts that meet FDA approval for use by pharmaceutical and biotech manufacturers.