PW: What’s the most significant change you’ve seen lately in packaging machinery?

Butler: So much is servo-driven these days. From material feed, to bag-length measurement, to changeover, so much is moving toward servo controls. The change has been underway for a number of years, of course, but it seems so much more noticeable now. You need a solid understanding of what they’re calling ‘mechatronics’ if you want to be successful with packaging machinery today. That’s why the packaging schools like Michigan State are offering courses in mechatronics.

PW: How does this affect your company from a personnel standpoint?

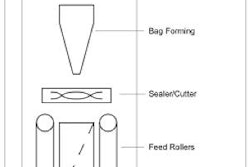

Butler: It makes us view the position of maintenance engineer a little differently. If we’re considering a new candidate, the person now needs a background in PLCs and controls. And the people already on board who are responsible for packaging machinery maintenance need to seek out courses on mechatronics and machine controls. It’s a matter of keeping up to date with what is really a moving target. Even PLCs in some cases are being replaced as machines grow more PC-based in the way that they’re programmed. International standards for communications between controls and servo drives, like SERCOS [SErial Real-time COmmunications System], for instance, are in evidence more than ever. Our vertical form/fill/seal baggers are a case in point. Two of them rely on fairly conventional PLCs. But the newest one is like a blend of PC and PLC, and communications take place over the SERCOS network.

PW: I see Tennessee Tech University is right here in Cookeville. Do you get involved with them much?

Butler: Recently we challenged their mechanical engineering students to design a system to lift bulk sacks of powdered foods. They brought us three ideas and we selected one to implement here in our plant. —Pat Reynolds