How does one of the leading manufacturers of over-the-counter pharmaceutical products enter the food business? If you're McNeil Consumer Healthcare, a unit of Johnson & Johnson, you do it by purchasing the best packaging equipment available and installing it at a contract packager that knows food like Baryshnikov knows ballet.

The particular food in question is McNeil's Benecol®, the so-called "miracle margarine" that contains a unique dietary ingredient, plant stanol ester, that has been shown to lower LDL, the "bad" cholesterol, without lowering HDL, the "good" cholesterol. When McNeil's development team emerged from the lab with a cholesterol-reducing spread that was ready for the marketplace, time to market was absolutely critical. A contract packager was the obvious answer, says Cameron Meikle, director of operations for nutritional products at Fort Washington, PA-based McNeil.

"We're an over-the-counter pharmaceutical products company, and as such we have plenty of liquid- and solid-dose packaging capacity at our plants," explains contract site manager Doug Buddle. "But Benecol is a food product, and as we looked at the kind of infrastructure we'd need to get into the fats and oils business, we realized that not only would it have been cost-prohibitive, but time to market would have been too long. So we went to people whose core business is making margarines and spreads."

"This was a totally new business for all of us," adds principal engineer Dan Backich. "So we all had to learn not only a new business, but new vendors as well. In the end, I think we picked excellent equipment, and we have a top-notch contractor doing the filling for us."

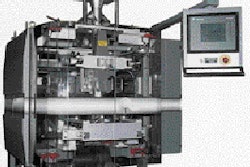

The central piece of equipment in the Benecol packaging line is a model THL-30/37 thermoform/fill/seal system from Hassia USA (Morganville, NJ). With a maximum rated speed of 30 cycles/min, it thermoforms by means of pneumatically-driven plug assist, compressed air and water-cooled molds. (Number of cavities per cycle is information McNeil considers proprietary. The firm also chooses not to identify its contract packager.)

The finished package emerging from the Hassia machine is a perforated strip of three units, each unit containing 8 g of Benecol spread. According to Buddle, the portion-pack approach was selected for a specific reason.

"For the product to be successful, consumers have to eat a certain amount every day, and we wanted to make it as easy as possible for them to do that," says Buddle. Each portion-packed unit represents one of the three daily servings that are recommended. Polish off a strip of three units each day and your cholesterol count should be on its way down.

To thermoform or not

Having decided on portion packing, McNeil faced another choice: Should the packs be preformed or thermoformed in-line?

"In looking at the two alternatives," says Buddle, "form/fill/seal was the winner from a cost perspective. But cost was only one factor. The look of the finished cup was also a key. With the Hassia machinery, we were able to design the cavity to any size we wanted. We feel it delivers a more elegant-looking package and creates a higher perception of value in the mind of the consumer."

A third consideration in machine selection, says Backich, was single-source responsibility. "From forming to filling to sealing to collating to cartoning, we wanted single-source responsibility," says Backich. The source in this case was Hassia USA, though not every piece of equipment in the line is manufactured by Hassia.

"We had a very tight delivery schedule, and it's not a simple task to collate and carton a three-pack like this," says Buddle. "As Hassia analyzed our needs and our time frame, they felt the best solution for cartoning was a robotic pick-and-place system from a supplier they had worked with in the past when tight time frames were an issue." The robotic cartoner selected by McNeil and Hassia is a Model SMB-F2 from Schubert (Dallas, TX).

Cartoning equipment, too

The third and fourth pieces of equipment in the line, both from Schubert, are a carton erector and carton closer/leaflet inserter. But first in line is the Hassia tf/f/s system, which forms packages from 15-mil high-impact polystyrene supplied by Vinyl Plastics Inc. (Sheboygan Falls, WI). Depth of draw is 16 mm (0.63").

In a separate station immediately after thermoforming, a corner tab is scored into the material. Volumetric piston filling is next, followed by heat-sealing of the foil-based lidding material. Supplied by algroup wheaton (Shelbyville, KY), the lidding material is a two-layer adhesive lamination of 0.0005" foil and 48-ga polyester. The foil is gravure-printed in four colors and given a protective overlacquer. The polyester layer is coated for heat-sealing.

Next is a punch station that cuts individual packs free from the web except for the scored area that keeps the cups in their three-unit format. Finished three-packs are then discharged from the machine onto a transfer conveyor.

In production now since March, the Hassia machine has met all of McNeil's expectations, says Backich.

"We looked at some of their equipment in operation, both in the U.S. and in Europe," says Backich. "We talked to the people who operate the equipment, too, and the [positive] feedback we heard was basically the same from everybody. Sure enough, when our equipment arrived, after we went through training and debugging, it ran commercially day in and day out."

Collating infeed

Shortly after discharge from the Hassia machine, strips of three-packs drop into a flighted conveyor that serves as a collating infeed to the Schubert robotic cartoner. Feeding the cartoner is an automatic carton erector. Cartons are filled 12 at a time. The robotic pick-and-place head uses vacuum cups to pick up 12 three-count strips and deposit them into the waiting cartons. After seven strokes by the robot, the 12 cartons are full. Each carton holds seven strips of three servings, or a one-week supply. Filled cartons are automatically conveyed out of the carton filling station and into the carton sealing machine. Case packing is currently done manually.

Supplied by PCI (Pennsauken, NJ), the seal-end carton with recloseable tuck top is made of 18-pt solid bleached sulfate and is printed offset in six colors plus acrylic coating. Carton design, executed by The Coleman Group (New York, NY), was especially challenging because it involved not just a new brand but an entirely new concept in the supermarket: a food product that claims to improve cholesterol levels.

"We depended on The Coleman Group to provide the design skills they typically apply to our pharmaceutical packaging, such as Tylenol, along with the vast experience they have in designing appetizing food packaging," says McNeil's Peter Miller, vice president of marketing. The carton design that emerged conveys the special nature of the brand and its benefit, but it also emphasizes appetite appeal.

Merchandised nationwide alongside margarines and butters in the supermarket refrigerated case, Benecol spread sells for about $4.99 per carton. Print and TV ads gave the May launch a big boost, and the recent introduction of a Benecol salad dressing should add more fuel to the Benecol fire. But the spread came first, and Backich emphasizes the critical role packaging played in getting that product off the ground. As he puts it, "It was a great display of teamwork by Hassia, Schubert and McNeil to meet a tight deadline."