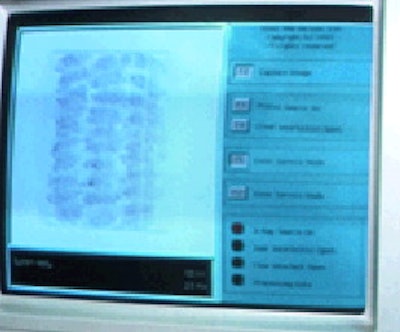

Plant engineer Steve Moran relates how operators would dial down the sensitivity of the detectors to eliminate the false rejects, rendering the machines useless. As an alternative, Herr's purchased two X-ray inspection systems from EG&G Instruments (Oak Ridge, TN), the most recent of which was installed a year ago. The two machines are located just outside the packaging area, one on each of the main conveyors carrying cases into the warehouse area. One, placed on the conveyor from the allied snacks section, inspects the aggregate output of 20 packaging lines; the other inspects the output from Herr's 15 potato chip lines. The inspection systems consist of an X-ray tunnel (resembling an oversized heat tunnel) and a desktop computer running custom software from EG&G. On the display of the computer is a real-time graphical representation of the X-rayed image. Cases travel through the machine on a 100'/min conveyor. The real power of the X-ray machine is its ability to catch not just metal but any foreign substance including wood, plastic or cloth. The machine works by sensing the density of an object; if the density is outside preset limits, it triggers a reject. Herr's has it tuned to detect particulates down to 3 mm in diameter. Detecting smaller particulates is possible, but it requires tuning the sensitivity to a specific product. "The whole theory of the X-ray is based on density," explains Moran. "We're running everything from a dense pretzel nugget to a delicate cheese curl through this machine. So we can't have the machine as finely tuned as the one that's dedicated to potato chips. However, we do find that it does an excellent job." Moran acknowledges the X-ray machines weren't an inexpensive solution, each costing ten times as much as a metal detector. But when cost is projected over 35 packaging lines, it's a more economical solution.