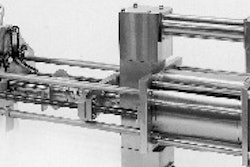

Responding to an Occupational Safety and Health Administration recommendation that bundled food packages shipped to retailers be maximized at 40 lb instead of 60, Savannah Foods re-examined its venerable paper bundling operation. It realized it was time not only to change bundle sizes but equipment as well. After evaluating equipment at one or two packaging shows, the Savannah, GA-based firm purchased two Model APB-TE 3200 CM-S shrink film bundlers from Automation Packaging (Tampa, FL). The first was installed in Savannah's Clewiston, FL, plant last December. A few months later, the second machine went into the firm's Savannah, GA, operation. At Clewiston, where 5-lb bags are now bundled in groups of eight instead of 12, bundles per minute stayed at about 16, says chief packaging engineer Derek Kight. "But efficiency is much improved because there is far less downtime," he says. Other benefits include savings in material costs and a reduction in damaged bags and the mess they cause. The improvement in efficiency is largely a function of how smoothly the new bundler runs compared to its predecessor. "The paper bundler had a number of air-actuated folding arms to wrap the paper around the bundles, and these often tore a bag," says Kight. When that happened, sugar spilled and time had to be spent cleaning up and getting the bundler working again. An added advantage of the clear film is that the contents of the bundles are easily identified. "It helps in warehousing, both at ours and the customer's plant, that you can see at a glance that these are sugar bags," says Kight. Customers have been pleased not only by the clarity of the wrap, adds Kight, but by the ease with which they can remove it when placing the bags on the retail shelf. But of all the benefits Savannah now enjoys, material cost savings may be the most significant. Kight says the recent softening in paper prices makes it difficult to quantify the precise savings. He also observes that it's only a matter of time before the pricing pendulum swings again. But for now the use of low-density polyethylene in place of kraft paper brings a cost savings that is appreciable, says Kight. The material is supplied by distributor Unisource (Savannah, GA). Three fillers At Clewiston, bags are filled on three systems that did not change when the API equipment was installed. Included in the equipment supplied by API is a lane divider situated about 30' ahead of the bundler's infeed. Basically a gate that directs bags down one lane for a while and then down another, it delivers a steady two-across flow of bags to the bundler. At the bundler infeed, a mechanical stop retracts to release four pairs of bags into the machine. A pusher plate then makes a stroke perpendicular to the flow of incoming bags, thus pushing the eight bags through the film curtain. The pusher plate retracts, and the next cycle begins. Film is fed from both a top and a bottom roll, and the two meet at the seal bar. Each time the seal bar closes, it forms the trailing seal for the bundle that is entering the shrink tunnel and the leading seal for the bundle just approaching the film curtain. Moments before entering the heat tunnel, each bundle passes through a fold-and-tack station. Stationary forming rods fold excess film on both sides and tack it with a heat gun. Then, following the shrink tunnel, pressing rollers smooth the sides of the bundles. The end result is that the film fully encloses the pack without bulls-eyes. To avoid frequent stops for film replenishment, Savannah typically loads large-diameter rollstock. An overhead hoist on a monorail makes it easy to swing these into position when needed. The machine is also customized so that it can function reliably in the harsh environment of the sugar plant. The bearings, for instance, are specifically selected by API to resist the powdery environment. There's also a positive pressure in the electrical enclosure to keep it dust-free. Aside from the installation of the new shrink bundler, one other change in the Clewiston operation is in the product identification and production date coding of the bundles. Formerly this information was ink-jet coded on each bundle. Now the ink-jet units are gone and instead a label is applied to each side of each stretch-wrapped pallet. The API system has been running since December in the Clewiston plant, and general manager T.K. Merritt reports complete satisfaction with the new bundling operation. "It's made our operation cleaner, faster, and more efficient," he says.