This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

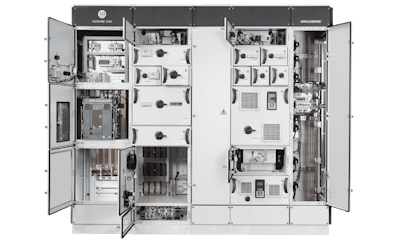

Rockwell Automation, Inc., the largest company dedicated to industrial automation and digital transformation, launches a new low voltage motor control center (MCC) for IEC markets globally, the FLEXLINE™ 3500. With this motor control center, manufacturers can unlock production data and increase uptime and productivity through a portfolio of smart products.

In manufacturing and processing operations, every production minute counts. Yet, it’s reported that the average global manufacturer faces up to as much as 800 hours of equipment downtime per year. Depending on the industry, downtime can cost $100,000 per hour or more. By integrating with smart motor control devices, the FLEXLINE 3500 MCC delivers real-time operation and diagnostic data for critical equipment. Global manufacturers rank predictive maintenance as the top strategic technology to reduce downtime.

“We survey thousands of manufacturers annually, and almost 75% identify ‘smart manufacturing’ solutions as critical to their organization’s success,” explained Diego Wilches, global product manager, Rockwell Automation. “Our connected technology delivers real-time operation data, letting manufacturers see and solve downtime problems before they occur. Some technology investments can see payback in as little as six months, explaining why 95% of Fortune 100 industrial companies use products and solutions from Rockwell Automation and our partners.”

The modular motor control center design is customizable to meet many low-voltage motor control applications and factory footprints while the technology is engineered for a wide range of industries, from food and beverage to oil and gas. And when FLEXLINE 3500 motor control centers are integrated with smart variable frequency drives, manufacturers can significantly reduce power consumption.

Additionally, the motor control center is engineered to integrate motor control and power distribution into one centralized package, meeting IEC 61439-1&2 standards for global customers.

The smart devices within FLEXLINE motor control centers help deliver significant benefits:

- Reduce unplanned downtime with alarms and advanced diagnostic information

- Reduce maintenance and energy costs

- Increase production throughput

- Improve plant and personnel safety

- Reduce engineering and commissioning costs

“Incorporating intelligence into manufacturing is a major shift we are seeing manufacturers deploy strategically. And with the introduction of the FLEXLINE 3500 motor control center, Rockwell Automation brings greater insights to plant operators,” said Craig Resnick, vice president, consulting, ARC Advisory Group. “By enabling more data-driven decision making through smart motor control technology, manufacturers can improve profitability, productivity and operational efficiency.”

The specifications of the new FLEXLINE 3500 MCC match a wide range of industrial applications and manufacturing needs.