Contract packager PCI’s multimillion-dollar ongoing investment in serialization technology, packaging equipment and controls not only helps its global pharmaceutical/biopharmaceutical customers meet serialization requirements, but also is expected to deliver a return on investment for the CP, based in large part on capturing future business.

Another financial benefit: Serialization technology renders some equipment redundant—in this instance checkweighers—saving capital investment costs.

The big picture

For the past two years, PCI addressed serialization through a combination of in-house-engineered solutions and/or customer systems. Now, the CP has established a global standard for its enterprise-level serialization efforts that employs numerous technologies, including the following:

• Antares Vision modular technology platform that integrates into PCI’s global packaging operations, as well as the IT architecture for aggregation and commissioning, batch handling of serialized numbers, and company-to-company data exchange.

• Integration support from Xyntek in the U.S. and Crest Solutions in Europe.

“The key tenet for our serialization technology partner search was PCI’s commitment to providing the industry’s leading customer experience,” says Ian Parsonage, the company’s Senior Director of Global Serialization. “We wanted to partner with a proven solutions provider that offered a technology that was flexible and adaptable to our individual client needs with the intent to make the client experience as easy as possible. Serialization can be complex, but whatever we can do at PCI to make our customers’ lives easier, the better off we all are. So far our clients have been pleased with the approach and the experience.”

At the time of PCI’s Enterprise serialization efforts, PCI clients were at varying levels of readiness in executing their own global strategies. These clients include large, traditional “Big Pharma” profile companies, mid-sized and small and emerging pharmaceutical and biotech firms.

PCI notes that several progressive-minded companies opted to aggressively move forward with their commercial serialization activities ahead of the 2017 regulatory requirements, thereby establishing the priority for PCI’s global equipment installations.

With that in mind, the contract packager targeted its largest operational center in Rockford, Ill. as its first installation location. The scope included multiple line integration installations across several packaging formats and technologies, as well as stand-alone “flex suite” installations, enabling PCI to provide inline solutions for serialization as well as a finishing solution for products needing codes to be added post-packaging. The successful implementation at Rockford provided a robust platform for subsequent installations at PCI’s headquarters in Philadelphia and at follow-on installations at its European sites.

Key lessons learned

Pharmaceutical and biotech companies need to allocate the appropriate amount of time for serialization implementation into their strategies,” says Ken Richardson, Vice President of Global Engineering for PCI. “The single biggest factor we see when working with clients is the impact to artwork. The process for artwork updates within their company-specific systems and procedures can really encumber the overall project plan.

“We see that many pharmaceutical companies do not allocate enough time in the total project scope. We try to engage them as early as possible to sit down and work through the project scope, deliverables and timeline, and commonly address many points they may not have even considered. With the proper engagement and dialogue at the onset, we can help provide the guidance to ensure a smooth and efficient implementation.”

Jeannie Metzinger, PCI’s Vice President of Quality and Regulatory, notes, “Serialization adds one more layer of complexity to packaging operations, and companies need to assure a robust quality approach to mitigate the additional risk imposed from the complexity of serialization.

“There are additional handoffs and documentation between companies, additional inspection technologies and criteria, and now additional points of consideration for established operational practices. Some companies are implementing serialization for the first time. There are many factors to address to ensure successful outcomes,” she says.

Parsonage notes that PCI has experienced additional benefits in its operations since installing serialization equipment and processes. “The inspection technologies and additional layers of inspection inherently drive effectiveness in the packaging process. We are seeing gains in process reliability, reductions in waste, and increased engagement from line personnel in producing a high-quality product. The nature of the serialization methodology also has enabled us to remove ancillary inspection systems such as checkweighing units because they have in effect become redundant. Successfully choosing the right serialization system has proven to be powerful in generating an even more robust and multilayered process.”

Industry readiness

Overall, Parsonage sees significant lack of readiness in the market. “PCI is actively working with leading industry organizations like GS1 and Global Track & Trace (GTT). Everything we hear and see points to a real need in the industry for serialization readiness. We anticipate a rush of market demand as the U.S. 2017 deadline approaches.”

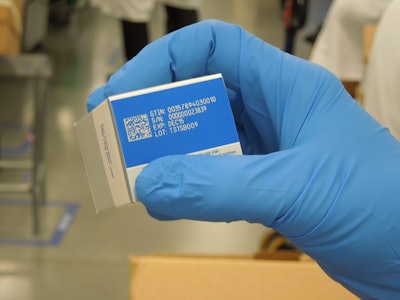

PCI’s approach to serialization installation features both direct line integration into packaging platforms such as bottling and cartoning lines, as well as standalone “FlexSuite™” technologies, an approach PCI says allows for offline coding, which has been well received by its customer base. The FlexSuite™ supports bottles as well as cartons, with sizes ranging from as small as a matchbox to as large as a shoebox.

“We have had several clients indicate they would send us their finished goods, products we didn’t necessarily package, but need the serialized codes added to meet the market requirements. The FlexSuite™ approach allows us to do just that efficiently and effectively,” says Parsonage.

International demands

While the U.S. requirements take effect in 2017, with the E.U. following in 2019 and 2026, many emerging markets have varying serialization requirements that are in effect or taking effect in 2016. PCI’s technologies have supported clients with ex-U.S. products and help to meet their serialization needs, including a recent success in expediting product for the South Korean market.

“A current client of ours, an industry leader in serialization and global anti-counterfeiting initiatives, approached us with an extremely tight timeline for getting serialized product into the South Korean market. Because of our collaborative approach and working relationship, we were able to meet some pretty aggressive delivery dates,” says Richardson.

Looking toward the future

Over the next two years, PCI anticipates significant market growth for serialization services. Additional capacity expansions for PCI’s serialization activities are underway for PCI’s main packaging facilities, with additional growth anticipated as companies take action on their serialization strategies to meet 2017 requirements.

“The market is just now starting to take shape,” says Parsonage. “With the lack of industry readiness there is tremendous activity to come. The U.S. and E.U. markets are sizeable and represent a large proportion of the global pharmaceutical demand, but growth in emerging markets will also be critical in the industry’s global anti-counterfeiting initiative. Right now we are only in the infancy of this industry adoption. Ultimately serialized codes will be every bit as commonplace as the UPC barcodes we see today.”

Bill Mitchell, President and CEO of PCI, notes, “At PCI we have fully embraced the opportunity that serialization presents to the pharmaceutical packaging business and overall pharmaceutical supply chain. We want to support our clients in meeting their regulatory obligations as they relate to the DQSA, but moreover we stand behind the broader effort to increase patient safety and security. We have invested substantial capital and resources to be a leader in the area of serialization because we see tremendous benefit to patients around the world.”