Alibris, Inc., a leading marketer of new, used, and hard-to-find books, receives and ships thousands of book orders each day at its 100ꯠ-sq’ warehouse in Sparks, NV. The company sells books through its own Web site, as well as through partners such as Amazon.com, Barnes & Noble, and Borders book stores. Shipper packaging efficiencies are critical to maintaining optimum throughput capacity at the warehouse.

The three-touch method

Alibris prides itself on what the company calls its “three-touch” method—open, receive, and ship—the touches referring to the number of times a book is handled from the moment it enters the warehouse until it is sent to the customer.

When books arrive at the warehouse from a bookseller, an Alibris employee opens the packages. The books are then given to another employee or “receiver” who checks the individual book’s condition, keys in an order number to retrieve a printed-out packing slip, puts the packing slip inside the book, and places the book into the appropriate tote, depending on its sales channel or carrier assignment. When the bar-coded tote is filled, it is placed on a pneumatic conveyor belt and automatically routed to the correct packaging lane. Each book then is packaged, labeled, and shipped at a single station.

Smart sensing system

Director of operations Brian Duarte and vice president of operations Mark Nason are constantly evaluating ways to further improve productivity and cut operating costs. After reviewing various packaging options that stayed true to the three-touch method, they discovered the PriorityPak automated system from Sealed Air Corp.

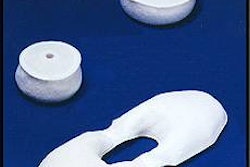

Using smart sensing technology, the PriorityPak system scans an item’s dimensions and then delivers the correct amount of Cold Seal cohesive-coated PriorityWrap rigid liner board from two supply rolls to the PriorityPak machine. The liner board is designed to provide stiffness and rigidity, and the cohesive coating only sticks to like-coated surfaces. As the two sheets of rigid board are fed into the packing machine, a patented XRS roller system creates a seal that suspends, centers, and locks the product (in this case, a book) between the board sheets, minimizing product shifting and providing additional corner protection. No staples are required, and the book stays securely snug within the packages, ready to endure the rigors of shipping and handling.

Mark Nason notes, “We were excited to learn there is an automated packaging system available that met our criteria of easy integration into our existing processes and offered reliability, ease of use, and reasonable cost.” The system also ensured consistent high-quality seals, which was not the case with some other equipment Nason and Duarte had observed in action.

Installation and start-up

Before system installation, Mike Ovesen, an automated systems specialist for Sealed Air Corp., provided hands-on assistance to determine optimum type and size of packaging materials and the number of roll changes that would be needed in a typical day of operations. Ovesen also provided final package samples so that Alibris could conduct shipping endurance tests and evaluate package aesthetics.

Alibris installed the PriorityPak system in May 2005. For three days, Sealed Air personnel oversaw the installation, trained Alibris staffers on the system’s use, and monitored to ensure it was running properly.

“The team from Sealed Air trained me and three others on how to use the system,” says Duarte. “However, there really was not much training needed because the PriorityPak system is very intuitive and easy to use.”

For multiple-book orders, Alibris also can incorporate Sealed Air’s Fill-Air inflatable cushions for void-fill in cartons, Bubble Mask adhesive-coated air cellular cushioning, and Cell-Aire polyethylene foam to line the bottoms of the cartons. The multiple-book packs, which represent only about 20% of Alibris’ shipments, are manually loaded into cartons, typically packed with Fill-Air cushioning material, and manually taped.

A Model Z4M direct thermal print-and-apply labeling system from Zebra Technologies produces and applies bar-coded pressure-sensitive paper labels to the book packs.

In-plant performance

Almost immediately after the installation, Alibris experienced increased productivity. According to Nason, the system enables the company to produce packs at more than twice the rate achieved with the previous board “t-fold” package system. The company now averages 2ꯠ to 3ꯠ packages per day processed through a single PriorityPak system.

Once a tote filled with books is conveyed to the packaging lane, the operator removes each book from the tote, removes the packaging slip from inside the book, and scans it. The scan alerts the packing system of the proper address, postage, and other carrier information to print on the label. The operator places the book on the bottom material web roll of the PriorityWrap rigid board and presses a button to begin the packaging process. As the book moves through the system, the sensing technology scans the book’s dimensions to deliver the correct amount of cohesive-coated rigid board from the supply rolls. The specially formulated cohesive sticks to itself to create seals adjacent to all four sides of the book. Because the cohesive-coated board adheres only to itself, any potential glue residue damage to the books and book jackets is averted. The print-and-apply label system produces the labels and applies them securely to the top web of the rigid board packaging. The finished package then is dropped onto a conveyor belt and delivered to a shipping bin. The entire packaging process takes only seconds per book.

Nason comments, “We were floored with the workmanship of the system. And it is twice as fast as any other packaging system we evaluated. It truly is top-notch.”

Accounting book benefits

Alibris has experienced a marked reduction in reports from the post office regarding losses due to book fall-outs or label separations. There was a 25% reduction in such losses during the first month of the new system’s use. In addition, because the structure of the package eliminates book shifting inside the package, incidence of book scuffing has been greatly reduced.

Furthermore, because the new packaging is approximately 5 oz lighter per book pack than the previously used t-folds, Alibris is saving 10 to 20% on overall international shipping costs. Domestically, because of the low profile of the new package, a higher percentage of packages are eligible for flat rate shipping, which saves the company approximately 10% in postage costs.

Initially, Nason projected that Alibris would achieve return on investment within about six months of installation and start-up of the new packing system. That goal was achieved and exceeded. Annual savings in postage, packaging materials, and labor are now estimated at about $300ꯠ.

The company is contemplating a second PriorityPak system installation in the future, if an additional machine is needed to meet growing production needs. “The modular design enables us to easily add more applications and features at a later date,” says Nason.