Label development is a balance of marketing goals, branding platforms, shelf impact, and consistent presentation. It’s tempting to go strong in one of these directions, but it will usually be at the detriment of the others. By following best practices as you develop your labeling strategy, you can succeed in every direction.

1. Don’t let the label be an afterthought. The container and the label should always work together physically and aesthetically, and choosing certain label methods will affect container decisions and design. Considering all your options in the earliest stages is prudent, and locking in the preferred label method as quickly as possible will get your package to market faster with fewer missteps.

2. Accelerate package design changes. Most CPG companies wish they could make packaging changes more quickly. The traditional approach of innovating new package concepts for individual brands and packages may be the culprit. Instead, many brand owners are starting to actively invite suppliers to pitch new ideas during an “innovation day” that brings in many new ideas at one time.

3. Manage the design intent. Know at what point you will want to stop involving the package design firm, depending on your production arrangements and brand management expectations. On one hand, if communication stops too early in the process, the production and engineering teams may alter the design in a way that departs from the carefully considered design intent. On the other hand, engaging the package design firm too far into the process can potentially slow down the project and add cost. Because of their commitment to the designs, more and more package design firms are offering production management services through final delivery.

4. Don’t miss the forest for the trees. Instead of looking at the label in isolation, consider how it’s going to be displayed in the context of the shelf set. Will your design look appropriate for the category? Does the label provide enough contrast to be noticed? Also, be careful that your beautiful label design isn’t obscured by your retail-ready display or in other promotional contexts. For instance, ready-to-drink soft drink companies have redesigned their labels so that the brand and flavor names are always at the top of the container for maximum visibility in the “visi-coolers” commonly found in convenience stores.

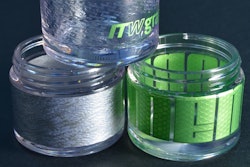

5. Think about label functionality beyond decoration. Ask what else you can expect of the label. Do you need to hide the product? (Not all products are pretty.) What compliance or regulatory information is required? Will regulations be changing in the near future? Can you cross-promote other products in your portfolio across categories? Can helpful information increase the amount of product your consumer uses? Will some sort of functionality make it easier to open? For example, adding a grip surface to the label can be much cheaper than molding a texture into the container.

6. Recognize that, for the consumer, less means more. For CPG applications, keep a maximum of three or four primary messages on the label—product name, brand name, serving size, and one benefit or feature claim. With so many choices on the shelves, a label crowded with too many text and graphic elements can confuse and frustrate shoppers. Further, modern austerity in design often projects the product as premium.

7. Reduce label materials. Manufacturers are offering more thin labels options than ever before, but be sure to test their performance before committing long-term. For shorter runs or with brands with many SKUs, consider digital printing to reduce waste and storage costs. Combine labels whenever possible by reducing unnecessary information. Do you really need side labels, a neck label, or even a back label? Promote recyclability by using processes and effects that can be taken in most recycling streams.

8. Appeal to consumers’ better angels. Today’s crop of consumers is smarter and more environmentally conscious that their predecessors. Successful CPG companies need not only appeal to a broad visual aesthetic, but also to a broad public consciousness. The success of direct-decorated aluminum bottles is due, in part, to consumers’ awareness that aluminum has a great record of recycling. The public was quick to recognize that even a less-distinctive container has some advantages in our environmentally conscious world.

Liked this article? Download the entire playbook here.