Netherlands-based vegetable seed marketer Bejo Zaden B.V. serves farmers and other professional cultivators around the globe. Focused entirely on the breeding, production, processing, packaging, and marketing of vegetable seeds for professional cultivation, Bejo specializes in 38 crops, encompassing some 700 total seed varieties.

Bulk bags are packaged in 5 to 25 kilogram weights, using a bagging machine from Bag Treatment Holland (www.bth-bv.nl). An intermediate package size range includes weights between 100 grams and one kilogram, produced on two vertical form/fill/seal machines from Hastamat (www.hastamat.com). And in a third size range, the company packs up to 30 different batches daily in 170x115mm sachet packet dimensions for package weights from 2 to 80 grams.

These sachets are produced on three different form/fill/seal machines—one from Rovema (www.rovema.com), one from Laudenberg (www.laudenberg.de), and one from Hassia (www.hassia.de). The sachet structure is a laminated paper/foil/polyethylene supplied by Bischof & Klein (www.bischof-und-klein.de). The sachets are supplied flexo-printed in three colors. Additional product-specific data is thermo-transfer-printed in-line at Bejo. Until recently, all these sachets were then manually packed into hand-lock cartons.

Upgrading cartoning operations

Bejo wanted to automate and increase the quality of its sachet carton packaging. Towards that end, in October 2006, Bejo Zaden installed a Breeze horizontal intermittent-motion cartoner, manufactured by Langenpac (www.langenpac.com), a member of the Molins Packaging Machinery Group, at the Bejo facility near Alkmaar in the northern Netherlands.

The various seed sachet packs may vary slightly in size/weight, depending on the vegetable seed type—for example, carrots, cabbage, onions, etc. This difference in sachet size/weight must be accounted for during the counting/collating stage prior to carton loading.

To achieve this accountability, the Langenpac tower infeed is electronically synchronized with the existing sachet form/fill/seal packaging machinery. The Langenpac system counts the appropriate number of sachets at 60 sachets per minute to form collations of 5 or 10 per carton.

An integrated reject mechanism guards against incorrect spacing (including missed or double-deposits) of the seed sachet packets. The electronic coupling of the cartoning system with the sachet machine improves quality control of carton contents by positively identifying each sachet type along the entire feed path. A single-head rotary feeder squarely places each carton between chain lugs, protecting carton graphics as the cartons are carried along the line.

Arjen Slagter, group leader of the packaging and ordering department at Bejo Zaden, notes, “We decided to install the automated cartoner to reduce the amount of hand labor. Also, the automatic counting feature was an advantage. The most difficult part of this process was the fact that we pack many different batches every day. With every new batch the weight and volume of the sachet changes, and the number of sachets we need to put into the carton changes from 5-count to a 10-count pack.”

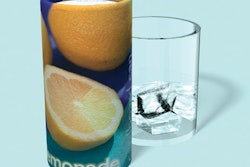

The carton dimensions are 118.0 x 59.0 x 171.0mm. Each carton features a window made of acetate foil with UV light protection. These cartons are supplied by Van Gorp Vouwkartonnages BV (www.van-gorp.nl).

Diverse language challenges

Because Bejo Zaden ships large quantities of its products to various countries, different languages normally would have to be printed on the cartons, depending on the destinations. But a more economical solution is to use a single type of carton bearing only the Bejo brand name, but featuring a cut-out carton window that allows visibility of the sachets within the carton. The product information is printed in different languages on the sachets themselves.

Installation & operation appraisal

“The installation of the Breeze took about one week,” reports Slagter. “Most of this time we used to adjust the infeed unit. Because we pack a lot of different volumes on this machine, it was very important that the filling of the carton went without any problems.

“We have put two special vibrating units in the bomb-bay tower to flatten the sachets and facilitate carton loading. The operator training was done in just a few hours because the machine is quite easy to operate. And the top of the machine can be opened for easy cleaning access.”

In terms of output improvement, Slagter explains, “The output is almost the same—5 or 10 cartons per minute, depending on what product we are running. But with the Breeze, we need only one person instead of two to man the cartoning line. We use the same carton size for both the 5-count and 10-counts sachet packs. So the only thing the operator has to do is push a button to change from 5 to 10 sachets in a carton. We don’t lose any time by changing the count format.”

In summary, Slagter says, “We are happy with the Breeze cartoning machine. We’ve been running it for more than six months, and the system is working perfectly.”