This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Ink is suitable for a variety of coding applications across industries such as food and drink, cosmetics, confectionery and tobacco.

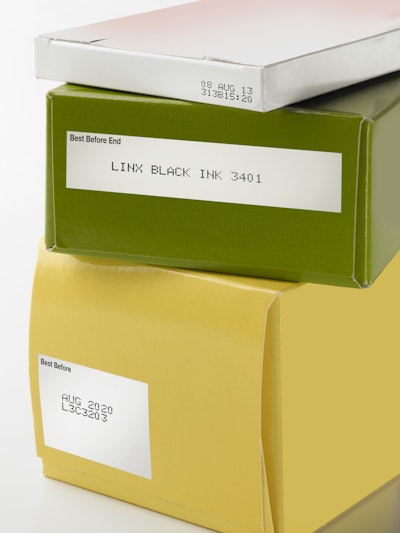

The new Linx Black Ink 3401 offers a fast drying time of one to three seconds on both porous and non-porous materials, as well as superior light fastness and excellent adhesion and contrast on a wide range of materials including paper, card, plastic and flow-wrap.

The ink has good general chemical resistance across many substances, which makes it resilient to chemical splash from alkalis, acids, water, alcohol, petrol and cutting fluid, and is capable of heat resistance of up to 30 minutes at 300°C with no adhesion or colour change.

Linx Black Ink 3401 joins the company’s existing range of MEK-free ethanol-based inks. It can be used with Linx’s market-leading 4900 and 7900 CIJ printers to provide a range of coding solutions for all types of production and packing line requirements, delivering consistently reliable and high quality codes.