This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

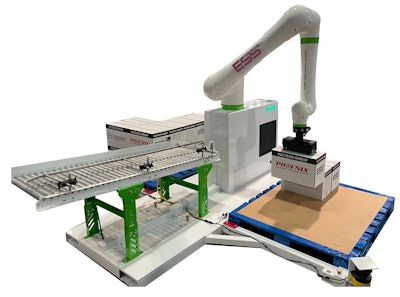

Created by ESS Technologies and Schneider Packaging Equipment, the install-ready, quick-start, small footprint, fully supported collaborative robot (cobot) is an off-the-shelf solution that optimizes valuable floor space, increases throughput, and improves flexibility.

Based on the Fanuc CRX-25iA collaborative robot, the compact cell features one or two pallet positions, each equipped with safety sensors that allow the robot to operate safely alongside employees. The CRX-25iA stops the moment it contacts anything solid.

Available in dual- or single-cell configurations, the robot can accommodate unit load heights up to 1,524mm (60 in.) and has a reach of 1,889mm (74 in.). The cell uses 120V, single-phase, 15A power and meets ANSI/PMMI B155.1 safety standards. The skid-ready machine base simplifies transport and installation.

Compact enough to fit any floor plan, the robot includes intuitive software that allows for quick startup. As production parameters change, additional pallet patterns can be programmed on-site, allowing the system to remain in service for years.

The ergonomic automation solution is suitable for palletizing vacuum-pickable pharmaceuticals, consumer packaged goods, cosmetics, and more with a maximum payload of 30 lb.