This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Strengthening food safety programs globally, Fortress Technology has launched a fully integrated, super-hygienic X-ray inspection system equipped with internal view cameras and an integrated automatic reject device to optimize floor space. Its powerful performance and defining attributes reflect its symbolic status and name. Get ready to view the Icon X-ray, the latest model of food inspection efficiency at PACK EXPO International 2024 (South building, Booth S-1758).

Steve Gidman, Founder and President of Fortress Technology will unveil how the Icon X-ray is already winning over food processors with its unparalleled productivity while simultaneously reassuring consumers with exceptional contaminant detection accuracy. Discover the innovative features of this high-speed X-ray system, designed to significantly enhance processing efficiency, consumer safety and contaminant detection in high-care food production facilities.

Inspecting and rejecting packaged chilled, baked and confectionery products, the Icon X-ray uses Fortress Technology’s proprietary IA+ algorithm. This provides unparalleled processing and detection power to adapt to variable-density products that present with metal, ceramic, glass and high- density plastic contaminants. In addition, IA+ allows for instant adaption to future machine learning features.

Prioritizing user safety, and with a constant inspection throughput of up to 200ppm, the Icon X-ray features internal cameras to vigilantly monitor product status and immediately address any operational bottlenecks. Processors can select optional transparent high-density windows on the sliding access panels that fully shield operators from X-rays as they observe the inspection process. The X-ray cabinet comes equipped with all required shielding, mitigating the costs associated with post-purchase safety modifications.

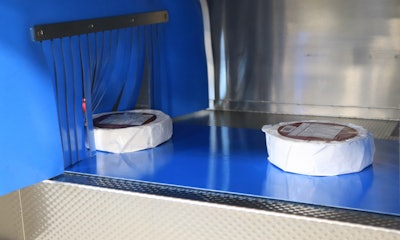

The hygienic Icon X-ray includes an integrated reject device, with the option to add other features, e.g. shielded sliding doors.

The hygienic Icon X-ray includes an integrated reject device, with the option to add other features, e.g. shielded sliding doors.

Robust and hygienic, the Icon X-ray comprises a fully enclosed, maintenance-free air-cooled generator. Unlike other food X-ray systems, the Fortress Icon X-ray doesn’t use an energy-intensive air conditioning unit.

The Icon X-ray’s ultra-hygienic design supports sanitation processes and increases plant productivity and food safety, with beveled, easy clean surfaces to promote water run-off, speed up drying time and prevent cross contact contamination. Created for high-care food environments, fully-sealed panels ensure that no cables are exposed to dust and other particulates. As a result, the Icon’s framework can withstand repeatable, high-pressure, high-temperature jet sprays, wash-downs or steam-cleaning procedures. Additional time-saving sanitation features include easily removable magnetic X-ray curtains, a quick release tight-fitting conveyor and IP69k-rated sensors.

The Icon X-ray offers networked data integration and reporting as standard features. For enhanced connectivity, processors have the option to incorporate network communication adapters to integrate with existing systems and support real-time data sharing and analysis in a variety of formats.

Facilitating seamless user interactions, the Icon X-ray’s 10-point touch industrial capacitive touchscreen display is responsive and intuitive. The ability to swipe, zoom and easily select an instruction saves time, minimizes stoppages and increases productivity.

“The Icon is truly an inspection gamechanger. Especially in the New Era of Smarter Food Safety. It adds a new level of food safety and traceability no longer reserved for the most elite food brands,” asserts Fortress Technology’s President, Steve Gidman.

The Icon X-ray comes with Fortress Technology’s highly valued Never Obsolete guarantee, ensuring equipment longevity and cost-savings for customers. It is one of 16 machines being showcased by Fortress, making booth S-1758 their biggest equipment presentation in the company’s history.