Headquartered in Singen, Germany, Maggi GmbH provides seasonings, broths, and sauces crafted to help consumers find creative cooking solutions. A subsidiary of Nestlé Germany AG, Maggi GmbH is part of a 143-year-old global brand owned by Nestlé SA that is best known for its Maggi Noodles, Maggi bouillon cubes, and Maggi-Würze seasoning sauce products.

In 2012, the Singen manufacturing plant—one of five in Germany—was facing packaging challenges on its “instant line,” responsible for filling into glass jars products that dissolve in hot water without needing to be cooked. According to Franz Finus, Maggi Project Manager, these include different types of bouillon cubes as well as instant sauces and granulated beef broth, which may be “free-flowing, non-free flowing, powdery, fatty, and/or granulated.”

The issues faced by Maggi were the result of outdated packaging equipment—a rotary filler from 1993—that caused frequent breakage of glass jars, complex and timely line changeover, and other issues. “The old system had a number of factors in its disfavor, and something had to be done,” says Finus.

In August 2012, Maggi began operation of a customized Optima MFL filling machine from Optima Packaging Group that not only addressed its problems with breakage and changeover time, but also tripled its speed, reduced noise emissions, and significantly enhanced its filling accuracy.

Portioning system allows accuracy

In engineering a filling solution for Maggi, Optima faced some challenges. Among them was how to handle the powdery and granulated products. Instant soups, sauces, and bouillon have a tendency to scatter when filled, while others are non-free flowing, so a technology needed to be developed to ensure dosing accuracy.

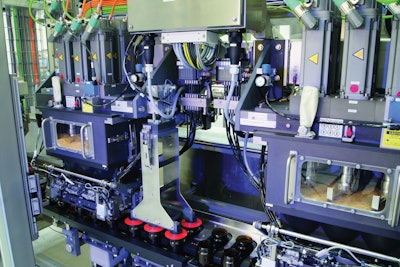

The solution is a customized modular linear filler that offers a portioning system comprising of six pre-dosers, six intermediate weighers, six top-up fillers, and six gross weighers. Using the principle of “programmable product addition,” the system first employs a pre-doser to fill the container to approximately 80% of the fill volume using a large auger filler. After filling, an intermediate weigher measures resulting fluctuations in dosing and determines the exact volume remaining to be filled. The difference is made up by a downstream top-up filler, after which a gross weight system registers the exact final weight and reduces any surplus product via the average value controller.

Filled containers then exit the machine and are conveyed to a dynamic checkweigher that classifies the products according to the EU Prepackage Directive and rejects packaging that is unsuitable for circulation.

“Our products are very expensive, and German packaging regulations specify very exact limits, which we must comply with. Neither overdosage nor underdosage is desirable. The measured averages were therefore a criterion for signing off on the line,” explains Finus.

Equally as crucial was the machine’s ability to eliminate glass breakage on the line. According to Finus, using the previous rotary filler, Maggi sometimes experienced glass breakage multiple times per shift when handling containers with round edges. “Reliable production without glass breakage is extremely important to us,” he says. “We needed a reliable, state-of-the-art production line.”

During operation of the new machine, glass containers are fed to the filling line in two lanes. Next, the containers are accumulated together and then separated into sets of 3x2. A rake transport system then gently and precisely moves the containers through the filler in sets of six. As Finus confirms, the new linear arrangement and gentle glass handling with the MFL have completely eliminated breakage.

Slower transport of the bottles has also brought another, unexpected, benefit: decreased noise emissions from 85 to less than 80 decibels, says Finus.

Changeover shortened, speed improved

Another major improvement over Maggi’s previous system is the MFL’s changeover flexibility. Simple format changes—for example, country-specific containers or special offers that contain 25% more product per package—now take just five to 10 minutes versus the hour required with the previous machine. “Now we have quite a few pluggable format parts and no more adjustments,” says Finus. “We refer to these unambiguous, pinpoint settings as ‘centerlining.’ We simply exchange three or four parts and are ready to produce again.”

Changing from one product to another—sometimes up to three times a day—is a more time- and labor-intensive process, as the new machine has 12 filling heads that all have to be cleaned. However, equipment optimizations have cut down the time to 100 min, and further optimizations are in development to make product less dusty and reduce mass fluctuations.

Combined, the improvements in dosing accuracy, gentle jar handling, and flexible changeover have increased Maggi’s throughput significantly, allowing it to triple output per cycle. “Now six containers are processed per machine cycle, instead of only two previously,” says Finus. “We can now fill 180 jars in 30 cycles, whereas the same task took 90 cycles with the old system.”

Machine output is dependent on the properties of the product being filled. For example, instant chicken bouillon is filled in 125-g jars at speeds to 240 containers/min. As for dosing accuracy, the average measured weight is 125.1 g with a standard deviation of 0.58 g.

Other requirements met

In working with Optima on the development of the new filling equipment, Maggi had other requirements as well, including space constraints, hygienic design, and an aggressive delivery deadline.

Since eliminating glass breakage was a major goal of the project, providing enough space to safely transport the bottles was key—despite the fact that Optima had a limited amount of space to work with. So as Finus explains, “the new system was built around the product feed,” with fixed locations for every corner of the machine. The resulting footprint of the machine is approximately 19 x 4.6 x 7.5 ft.

Maggi also required that the machine have a hygienic design in accordance with Nestlé’s specifications, which also relate to TPM (Total Productive Maintenance), a system that involves considerations such as centerlining, ease of access, color codes for lubrication, etc. Engineering a hygienic design required Optima to eliminate dirt traps where contaminants might hide, necessitating open cables on the machine without hollow profiles.

Maggi also needed to get the machine up and running by the beginning of its busy season. “Our ‘season’ starts in September, as there is more demand for soups and bouillons during the cold months of the year,” explains Finus. “Pre-production is thus essential. We succeeded in starting up production with the new system by August, just in time for the high season, but it was a bit of a wild ride.”

Contributing to the “wild ride” was trying to time the decommissioning of the old line and the installation of the new to minimize downtime, as parallel production was not possible due to a lack of space. To ensure the new line was ready before the old one was removed, Maggi filled product for two days at Optima’s facility under real conditions, using Maggi production staff. “We installed the original transport system and disassembled it again afterwards,” says Finus. “By then the decision was clear: all systems go. This approach allowed us to minimize the risk.” Once installed in the Maggi plant, the new line was producing salable product after two weeks.

Teamwork yields results

Since being installed in 2012, the Optima MFL has completely met Maggi’s expectations, which Finus attributes to the teamwork of the two companies and Optima’s expertise. “It was absolutely necessary that Maggi and Optima work in close collaboration,” he says.

“The system was designed together, and all details were discussed at length. Something like this would not have been possible with another company. We also would not have achieved our goal with an off-the-shelf system; it was clear that only an individual solution would work for us.

“We are undeniably more productive [with the new system]; the exact figures are available internally. The quicker format changeover is certainly a factor in this. We have now eliminated broken glass 100 percent. We are in complete compliance with our internal regulations for hygienic design. Noise emissions have been considerably reduced, and standard deviation has decreased significantly.”