Asymmetric containers are more problematic for filling than symmetric ones, but they’re little problem for Schwarz Pharma. The Seymour, IN-based pharmaceutical products company has packaged its oral solution powders into 4-L (1-gal) offset-neck high-density polyethylene bottles at rates around 20 bottles/min for years.

Not bad. Yet that wasn’t good enough to meet growing demand and future plans.

Last year, Schwarz replaced that line to double speeds to 40 bpm, and improved changeovers and cleanliness. The latter isn’t a mere trifling improvement: Enclosures for sequential, two-stage fillers help reduce the time needed for changeovers because there is less cleanup required. The enclosures also improve yields by reducing product loss, according to Schwarz project engineer Jimmy Cognata.

Yet speed increases weren’t the only improvement; Schwarz also called on the line to handle a new 2-L size as well as 16- and 24-oz symmetric bottles.

Twice the speed, double the package formats, and quadruple the bottle sizes: It all adds up to a productive operation for Schwarz Pharma.

“We replaced the whole line from the infeed to the exit,” Cognata explains. “We replaced the bottle descrambler, the bottle cleaner, the filling systems, the capper, the induction sealer, the labeler, and the case packer.”

Much of the line’s integration was done by NJM/CLI (www.njmcli.com), which has helped Schwarz with three other packaging production installs.

The new line was installed in February 2007 over a six-week period in which the new equipment was placed into the previous line’s footprint, though Schwarz also moved walls and added openings to others. That was followed by a three-week startup curve to debug, validate, and establish settings, according to Cognata. The line operates two shifts a day, five days a week, leaving some room for additional capacity if needed.

The generic oral solutions are distributed to hospitals and pharmacies under the brand name PEG, a line of powdered products used in conjunction with upper gastrointestinal tests to flush the system, plus adds electrolytes for replenishment. Product containers, marked with a fill line for adding water by medical personnel, are shipped as bottled powders.

Setting the pace

The bottles must be oriented—done mechanically—for filling downstream. The bottles’ orientation is controlled through filling, capping, and labeling. A Pace Packaging (www.pacepkg.com) bulk hopper and Omni-line M500 unscrambler handle the initial orientation.

Although Schwarz has used Pace unscramblers before, this one is uniquely different.

“We have four other Pace unscramblers,” says Cognata, “but because of the four-liter bottle, we use an infeed hopper that’s about 10 times the size of the others.” He says operators can dump as many as 125 bottles into the 165-cu-ft hopper.

This operation was where Schwarz was able to pick up the production pace and maintain it throughout the line. “Before we could only unload bottles six at a time,” he says. “Now we can dump a case of 24 at a time. This is more like a regular bottling line.”

The Pace unscrambler is one of Cognata’s favorite pieces of equipment on the line.

A pick-and-place robotic system that handled the orientation had dictated—and constrained—the speed of the previous line. It positioned bottles onto the infeed conveyor after removing them six-at-a-time from shippers. Later, the filled bottles were packed back into the cases.

The cases are in effect still used as reshippers, but not in the conventional sense, and not by Schwarz. “We’re reusing them by sending them back to the supplier, which happens to be located across the street,” Cognata says.

Next, the bottles are conveyed to a 14-station Orbit rotary air cleaner from McBrady Engineering (www.mcbradyengineering.com). “It picks up the bottles, inverts them, blows air in, and then pulls a vacuum to suck the air out before returning the bottles to the line,” Cognata explains.

The bottles are conveyed through a portal in the wall into a filling room that houses two All-Fill systems along with associated packaging systems. For its 2- and 4-L containers, Schwarz does the filling in two stages. For the symmetric, smaller bottles, the filling is done in one stage, and the bottles are conveyed directly to the second (rotary) filler. The current workhorse container is the 4-L bottle.

On the day of our visit, Schwarz was packaging PEG-3350, a product that contains 278 g net weight of product. Across its range of products, the first fill could be 9 g and the second fill could be up to 420 g; fill amounts vary by product formulation, Cognata says.

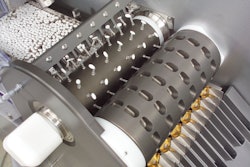

The first filler is an All-Fill (www.all-fill.com) Multi-Fill Series 70 linear filler with four auger filling stations and an optional enclosure. Just ahead of the system, a pick-and-place unit lifts four bottles at a time from the continuous-motion, flood-fill upstream conveyor and spaces them properly for four-up indexed filling. The line changes from continuous flow to indexing at the first filler and then returns to a continuous operation into the second filler and through the remainder of the line. The filler offers a feedback control for precise filling.

“There’s a feedback loop that will either slow down or speed up the auger,” Cognata explains. That’s done on a tare of the empty bottles ahead of the filler and with weigh scales after filling. “As the powder builds up on the auger over time on a shift, it has to go faster to provide the same amount and rate.” He reports that it provides a “very tight” 0.2% fill accuracy of the product’s crucial active ingredient.

The bottles exit the fill stations and are pushed onto a parallel conveyor moving in the opposite direction. This takes them around the curve of a U-shaped conveyor section where they are turned 90 deg ahead of the All-Fill 12-station, continuous-motion rotary filler. The enclosure is standard on All-Fill’s rotary machinery.

After exiting the filler, the bottles are conveyed toward the short leg of the oval layout for checkweighing and metal detection. The All-Fill Alpha checkweigher communicates with the filler to correct the fill amounts. Schwarz permits a final netweight fill tolerance within 5%, Cognata says, though All-Fill states the machine is capable of 1%.

A pneumatic reject station after the metal detector handles bad weights or contaminated products.

Containers proceed through a Kaps-All (www.kapsall.com) capper, a unit Cognata describes as unique because of how it accepts the bottle’s offset neck.

“Most in-line cappers have no problems with a standard bottle, but when you have an offset neck, there’s a challenge because you don’t want to cap it and indent the top of the bottle,” he says. Because of the offset nature of the containers, there’s more give in the bottle shoulders away from the sidewalls. For the Kaps-All six-head/three-station capper, that’s no problem.

Next, bottles convey through an inspection system from NJM/CLI. It verifies that the cap has been applied properly, i.e., that it’s tight and not skewed. “If it’s on loose, it will be rejected due to height,” Cognata points out.

Bottles continue to an Enercon Industries Corp. (www.enerconind.com) induction sealer that is used for about 20% of the line’s output, Cognata says. Adjustable for different height containers, the air-cooled unit features an All-in-One pivoting head for easy adjustment of dwell time for the range of closure sizes Schwarz can run. Enercon is tried and true as far as Cognata is concerned: “We’ve used Enercon sealers since at least the mid 1990s,” he says.

Bottles proceed down the long leg of the oval layout to the exit of the filling room and then to a room that houses the NJM/CLI Auto-Colt Model 326 print-and-apply labeler and the unscrambler. The labeler affixes labels printed with product name, product code, lot, expiration date, and NDC number to one of the bottle’s panels. The machine features a servo-driven label dispenser and offers a programmable logic controller with color touchscreen operator interface to control machine functions.

Before labels are applied, each one is inspected by an Optel Vision (www.optelvision.com) system. It reads and verifies the preprinted Code 128 bar code, as well as the freshly printed expiration date and lot number. The system includes two post-labeling optical inspection devices.

According to Cognata, FDA requires either 100% electronic inspection or 200% manual inspection for pharmaceuticals.

“The system also informs us whether the label’s on, if it’s skewed, or if it’s straight,” says Cognata. “We have nine other Optel vision systems.”

Bottles exit from that room into the warehouse to the robotic IMA (www.ima.com) top-loading case packer that loads the bottles either six or 12 to a case. Boxed product is then unitized for distribution. A second IMA case packer located adjacent to the first was installed to handle the 2-L bottle that Schwarz plans to introduce in the future.

Besides doubling speeds and improving changeover time, the line is also integrated for smoother, more efficient operations, Cognata notes. “When a machine is down, it automatically stops the upstream machine so the bottles don’t back up,” he says. “And when a machine starts running again, the upstream machines restart automatically.”

There have also been labor savings versus the prior line: Before, the line was manned by nine operators, now there are seven.

Overall, the line startup represents about a $3 million investment, Cognata says. Depending on the timing for new products, payback could be as short as less than two years, he says.

Thanks to due diligence by Schwarz and its vendors, the line has met the company’s expectations. “We really did our homework so everything is running as designed,” Cognata says, “and we’re getting the actual output speed that we requested. Sometimes you ask for a speed, and vendors give it to you, but only if you’re running at 100-percent capacity. Yet we’re hitting the actual speed that we requested while running this line at around 80 percent of capability.”