This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

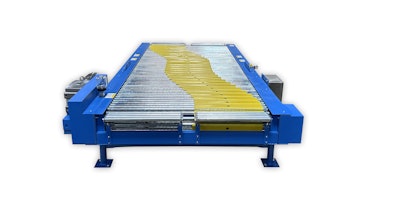

The Horizontal Switch from Stewart Systems provides a fast, efficient way to direct materials without slowing production. Designed for demanding material handling, it moves containers, components, and packaged goods smoothly between conveyors, maintaining a continuous flow of product. Its robust design ensures consistent performance even under the most challenging conditions, keeping operations running reliably day after day.

Built for seamless integration into new or existing systems, the Horizontal Switch features rugged construction with precise electromechanical or pneumatic actuation for accurate lane changes. The switch diverts, merges, or re-routes items quickly, improving throughput and operational flexibility across a variety of production processes.

Key features include:

· High-speed lane switching designed to minimize product handling time and maintain smooth flow

· Robust construction suitable for heavy-duty industrial environments and continuous use

· Designed for seamless integration with both new and existing conveyor systems.

· Engineered for lane flexibility—capable of merging, diverting, and sorting units efficiently

· Available in both pneumatic and electromechanical actuation

As a Middleby Food Processing brand, Stewart Systems delivers advanced equipment solutions for high-volume bread and bun production, as well as innovative material handling. The Horizontal Switch offers a dependable, high-performance way for industrial facilities to streamline multi-lane product handling and boost overall line efficiency.