This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

• Ensures shorter lead times and lower investment

• Flexibility helps companies adapt to changing market conditions

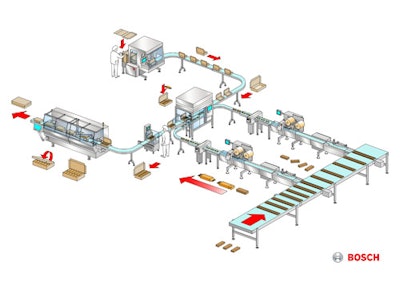

As part of this approach Bosch integrates standard modular equipment and makes minor modifications to meet application-specific, customer-defined requirements. The company is able to design comprehensive, flexible and cost-effective lines due to its extensive technology portfolio of form-fill-and-seal equipment, feeding solutions, product distribution technology, conveyors, carton formers and closers, robotic product handling systems, and other machines.

When implementing a Module ++ solution, Bosch considers integration requirements early in the project planning phase. This approach ensures the compatibility of standard machines, typically reducing engineering costs to less than three percent of the total investment and shortening lead times. The Module ++ concept also enables companies to source a complete solution from one supplier, lowering coordination costs and creating project management efficiencies. The solution is flexible, however, and does not preclude the integration of machines from outside vendors.

As product life-cycles shorten and demand for greater product variety grows, flexibility is an increasingly important feature of a packaging line. Module++ provides this production flexibility to help manufacturers adapt to changing market conditions and packaging styles. The lines use standard, modular machines, which can be redeployed in a wide variety of production arrangements to meet future needs or expanded to account for higher volume throughput.

"The Module ++ concept is designed to provide customers the highest return on their investment," says Craig Collett, at Bosch Packaging Technology. "By integrating standard machines in a customized manner to meet specific customer requirements, we can offer the highest level of performance and flexibility at the lowest cost."

• Flexibility helps companies adapt to changing market conditions

As part of this approach Bosch integrates standard modular equipment and makes minor modifications to meet application-specific, customer-defined requirements. The company is able to design comprehensive, flexible and cost-effective lines due to its extensive technology portfolio of form-fill-and-seal equipment, feeding solutions, product distribution technology, conveyors, carton formers and closers, robotic product handling systems, and other machines.

When implementing a Module ++ solution, Bosch considers integration requirements early in the project planning phase. This approach ensures the compatibility of standard machines, typically reducing engineering costs to less than three percent of the total investment and shortening lead times. The Module ++ concept also enables companies to source a complete solution from one supplier, lowering coordination costs and creating project management efficiencies. The solution is flexible, however, and does not preclude the integration of machines from outside vendors.

As product life-cycles shorten and demand for greater product variety grows, flexibility is an increasingly important feature of a packaging line. Module++ provides this production flexibility to help manufacturers adapt to changing market conditions and packaging styles. The lines use standard, modular machines, which can be redeployed in a wide variety of production arrangements to meet future needs or expanded to account for higher volume throughput.

"The Module ++ concept is designed to provide customers the highest return on their investment," says Craig Collett, at Bosch Packaging Technology. "By integrating standard machines in a customized manner to meet specific customer requirements, we can offer the highest level of performance and flexibility at the lowest cost."

Companies in this product

Videos from Syntegon