This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

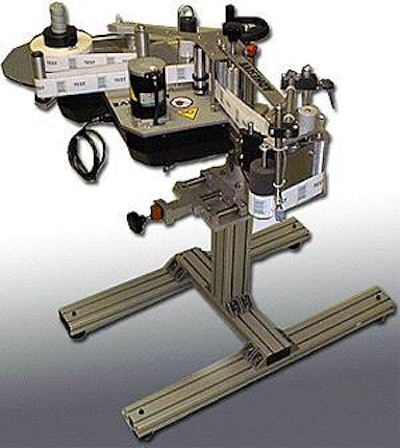

in-line pressure sensitive labeler... an accurate and versatile labeling system.

Advanced technology used on our higher speed, rotary machines, is used on the FlexStar ™ to provide a highly reliable, repeatable, and simple labeling system.

FEATURES:

• Modular stainless steel frame designs, sized for the application. System speeds from 20-400 bpm

• Precise and repeatable label placement accuracy using Pago labeling heads

• Can be configured for wrap, spot, front and back, and front-back-wrap applications

• Application recipes are stored in the label head controller for easy and quick size changes

• Adjustable label head support stands with digital indicators for quick and repeatable set up.

• Top hold down belt available

• Labeling system can be integrated into any conveyor system

• Easily handles a wide range of label and backing paper materials

• Can be set up to handle virtually any range of bottle, cap, and label sizes

• Label coding, bar code reading, vision inspection, rejection, and verification systems available per customer specifications (Pharma-Package)

• Bottle infeed systems options include spacing wheel, single or double helix, and eccentric positioner

• Allen Bradley electrics, PLC, and Panel View when supplied

• Standard 220/440V/3/60Hz. Special electrics can be accommodated

• Maximum roll O.D. to 16” unless separate vertical unwinder is provided

• Zero downtime – redundant head labeling option available

• Labeling systems for tubes, cartons, and cases also available