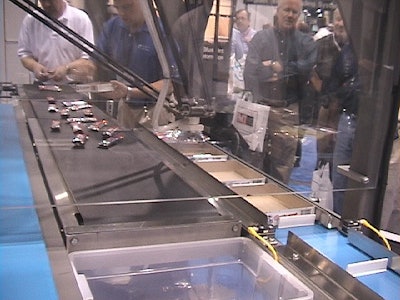

Central to the system is an ABB robot and controller. Blueprint Automation is responsible for the rest, including the end effector, the framework, and–in the case of the PELV installation–the integration of a Cognex In-Sight vision sysem. At PELV, the vision system allowed the end effector to find and pick randomly oriented items on a conveyor belt and place them on one of two outfeed conveyor belts. The robot took the input from the camera and then went directly to the product to reorient the product while placing it in the location or container specified. System operates at speeds to 200 picks/min.