A new Motor-controlled Zero-Pressure Accumulation (MZPA) pallet conveyor from Alba Manufacturing eliminates pneumatic clutches and their associated devices, replacing them with plug-and-play zone-control boxes from Rockwell Automation. Photoelectric sensors directly control the MZPA conveyor’s 230/460 VAC motors, and every accumulation zone is driven with a separate drive, thus eliminating mechanical and pneumatic components and associated maintenance costs.

A key benefit is that the conveyor can operate at elevations much lower than traditionally possible because there’s no longer any need to allow room for zone-to-zone chains running underneath. Because the chains associated with pneumatic-clutch conveyors are eliminated, the conveyor can operate at heights as low as 5.75” compared to the previous 18” minimum height limit.

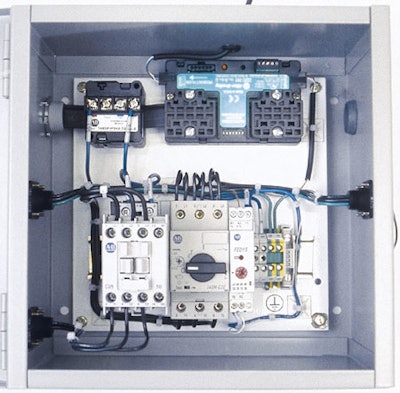

In zero-pressure accumulation applications, pallets move from one zone to the next at just the right time, preventing a buildup of pallets and alleviating pressure on pallet loads being conveyed. Controlling each zone in the MZPA conveyor (five zones are seen in the model shown here) is an Allen-Bradley 22ZC zone control system. Each zone uses an Allen-Bradley zone control panel that controls individual zone motors, eliminating mechanical and pneumatic components. In addition, an Allen-Bradley power supply panel provides the 24V DC control power and the necessary interconnecting cables.