This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

Emerson announced the launch of a solution for Dust Collector Monitoring and Control. A range of industries—including cement, mining and metals, chemicals and plastics, food and dairy, power, utilities, and more—handle materials that generate significant amounts of dust and particulate emissions. Automating dust collection monitoring is an effective way to optimize filtration, ensure environmental compliance, reduce maintenance, and avoid unplanned downtime.

This intelligent, easy-to-deploy solution also integrates with existing plant automation systems, helping to extend dust collector equipment life and boost overall operational efficiency.

Dust collectors are designed to capture potentially harmful airborne particles and fumes, which protects people and the environment, and for ensuring reliable equipment operation and maintaining environmental compliance. They vary in size, and are built to house filters, which must be monitored for performance, cleaned periodically with compressed air, and replaced when they fail or reach the end of their useful life.

Intelligent monitoring and control can reduce maintenance costs and the total cost of ownership. Smart filter cleaning can minimize energy costs and compressed air consumption. Detecting and identifying failed filters helps avoid regulatory penalties. In addition, extending filter life by as much as one year can result in savings of up to $18,000. Dust filters and pulsating solenoid valves play a critical role in many manufacturing and production operations, so preventing downtime and compressed air leakages can save thousands of dollars per hour.

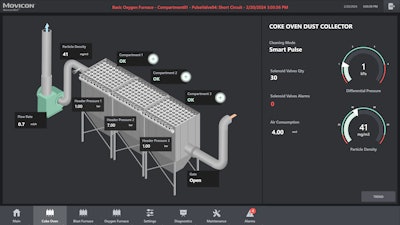

Recognizing these needs across multiple industries, Emerson offers a portfolio of elements necessary for high-performance dust collectors, including mechanical and automation products such as ASCO pulse valves, pilot boxes, and air tanks; pressure and particle concentration sensors; basic sequencer controllers; AVENTICS air flow sensors; Movicon HMI/SCADA visualization interfaces; and PACSystems PLC, I/O, and edge analytics.

“With this world-class and easily implemented solution, we aim to help our end users achieve greater operational efficiencies and gain valuable insights that reduce reactive maintenance, lower the risk of downtime, minimize energy consumption, and extend equipment life while addressing the knowledge gap by providing easily accessed information for operations personnel,” said Samuele Oliva, product marketing manager for dust collectors and alternative energy with Emerson’s discrete automation business.

Emerson’s standard dust collector monitoring and control solution combines these proven products and capabilities:

- Optimized control of pulse valves, including automated cleaning cycles of multiple filter lines.

- Movicon.NExT SCADA enabling remote monitoring, alerts, reporting, and integration with existing systems.

- PACSystems PLC controls and AVENTICS solenoids with built-in algorithm for efficient cleaning of multiple filter lines.

- QuickPanel+ HMI, which provides real-time diagnostics and early warning of fault detection.

- Scalable licensing based on pulse valve count (up to 500).

- ASCO P152 particle concentration sensors able to detect low dust levels and filter issues.

- Differential pressure monitoring with Rosemount pressure sensors and optional 4-20 mA compatibility.

- Compressed air, pressure, temperature, dust level and energy monitoring, plus predictive maintenance features.

By optimizing pulse valve use with advanced algorithms and predictive diagnostics, Emerson's dust collector monitoring and control solution can extend valve and bag life, reduce compressed air waste, and protect dust collector equipment while avoiding maintenance and downtime.