This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

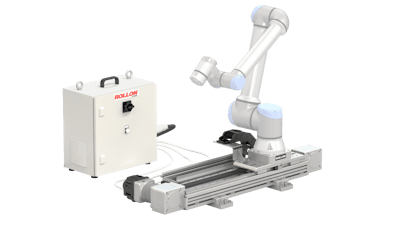

Rollon, a producer in linear motion solutions, announces the launch of its Cobot Transfer Unit (CTU), designed to push the boundaries of collaborative robot applications. With a series of enhancements, the CTU model offers improved flexibility, easier integration, and increased performance, making it the ideal solution for automation processes requiring extended reach.

The new CTU introduces a range of updates aimed at simplifying installation and maximizing efficiency. A transition to a new motor helps ensure reduced lead times, as it is readily available in stock. Additionally, the adoption of a 220V power supply—matching the voltage of Universal Robots—eliminates the need for industrial voltage, simplifying integration and reducing electrical complexities.

The revised match between CTU and robot sizes improves compatibility, now supporting the entire Universal Robots range, including the UR20 and UR30. The integration of the R-Smart actuator enhances system stiffness and load capacity, ensuring higher reliability in automation environments.

“Our latest CTU reflects Rollon’s commitment to continuous innovation and customer-driven design,” said Andrea Tosi, VP Technology at Rollon. “By optimizing the system architecture, we have created a solution that delivers seamless integration with Universal Robots, greater flexibility, and improved efficiency. With this launch, we are empowering manufacturers with a robust, plug-and-play motion solution that extends the capabilities of cobots like never before.”

Plug-and-play solution for integration

Rollon’s CTU is a turnkey system that includes an actuator, a gearbox, motor, electrical cabinet, and Rollon’s URCap software, allowing intuitive programming from the Universal Robots teach pendant. This enables users to control both the robot and the transfer unit through the same interface, eliminating the need for additional programming expertise.

With a steel-reinforced belt drive, extruded aluminium profile, and recirculating ball guides, the CTU offers high stiffness, lightweight construction, and strokes of up to 5500 mm, with extensions available upon request. The system also features various accessories for smooth integration, making it easy for customers to tailor the setup to their specific requirements.

Ideal for various applications

Designed for tasks such as light material handling, assembly, pick-and-place, and packaging, CTU’s compact design, easy installation, and flexible horizontal or vertical mounting supportadaptability across diverse automation environments.

With these advancements, Rollon continues to set standards in linear motion solutions, providing manufacturers with automation technology.