This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

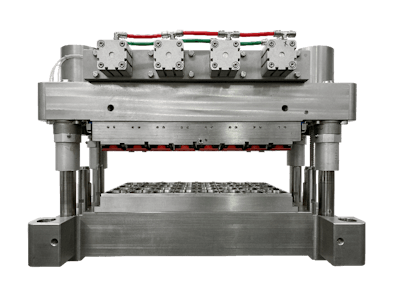

IMA Dairy & Food USA has made enhancements to the cutting tools utilized for its recently introduced Zero Technology, which helps food brands easily utilize sustainable monomaterial cup packages. Highlighted by an extractable central cutting unit (CCU) design, the innovation reduces production downtime for change-outs, minimizes spare part costs, and significantly raises the number of punches between sharpenings.

Ideally suited to IMA Erca, Hassia, and Intecma brands of form/fill/seal (FFS) machines, IMA Zero Technology utilizes a patented punch process providing high-quality cutting and pre-cutting of eco-conscious materials, such as PET, PP, and PLA. This allows for easily breaking multipacks into individual units—a cumbersome process that has limited the use of eco-friendly, monomaterial packaging materials in many cup applications.

Using an interchangeable cutting elements setup that allows individual tools components to be expediently replaced onsite, line stoppage can be reduced to 20 min rather than the 3 to 6 hr required to switch out an entire cutting tool. This simple “building block” approach also internalizes the servicing process, keeping the tool’s various components in-house for ongoing maintenance rather than shipping the entire cutting tool to an external entity.

Cost of ownership also is significantly reduced. This is because internally replacing CCUs piecemeal is far less expensive than replacing entire cutting tools externally. In addition, IMA’s Zero Technology cutting tools are more robust than conventional tools, yielding upwards of 7 million punches between sharpenings.

Zero Technology uses independent sleeves that allows cup design changes without the need to manufacture an entirely new thermoforming mold. The result is a by-design materials agnosticism that can help food brands take important next steps in sustainability. Notably, outfitting a formed cup with a PET lid and label creates a completely recyclable package for premium sustainability. In addition, the use of transparent monomaterials makes the product visible to consumers, enhancing on-shelf aesthetics.