This content was written and submitted by the supplier. It has only been modified to comply with this publication’s space and style.

The original PPT3000™ offers high-precision pressure and volume expansion testing capabilities for plastic containers. For companies that fill aluminum bottles as well, this version incorporates a number of additional testing routines designed exclusively for testing today’s light weight, formed aluminum bottles.

The PPT3000™ utilizes hydraulic (water) pressure as the testing medium when performing pressure and expansion tests. Pressurizing hydraulically affords a number of advantages including the precise control of pressurization, permitting complex loading curves and accurate volume expansion measurement.

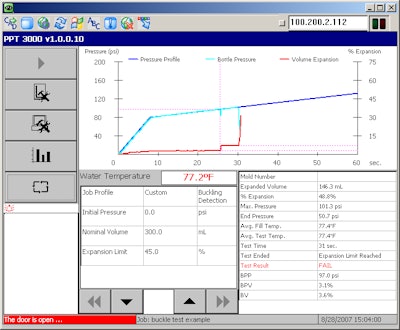

In the case of aluminum containers, precise control of pressure offers the ability to continuously monitor volume expansion as the container is pressurized and capture pressure data at the exact moment buckling occurs. The PPT3000™ test routines are designed around this capability and enable an operator to identify buckle point pressure, buckle point volume expansions and buckle volume expansion. This test also provides the operator with the ability to set the initial loading pressure and duration as well as the ramp rate. Test progress can be monitored in real time via the PPT3000™ display. At the completion of each test, a comprehensive test report is provided along with a test graph that displays the volume expansion and pressure where buckling occurred.

Pre-defined test profiles are provided with the PPT3000™ to support the needs of both container manufacturers and fillers for simple quality control testing as well as advanced package performance evaluation based on pressure, volume expansion or material utilization.