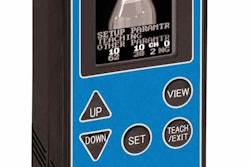

A “pause” input is provided to prevent false triggers if bottles back up through the unit. Other features include: single, ultrasonic sensor with programmable detection window; control box with Run/Set-Up mode selection; “sensor debounce” switch for adjustment to different bottle sizes; “teach” function for ease of set-up and changeover; and selectable reject device, air blow-off, and small cylinder or large cylinder design.

Phone: 414/671-3332